WC67Y-125X3200 CNC Hydraulic Press Brake Machine With DA66T System

1.

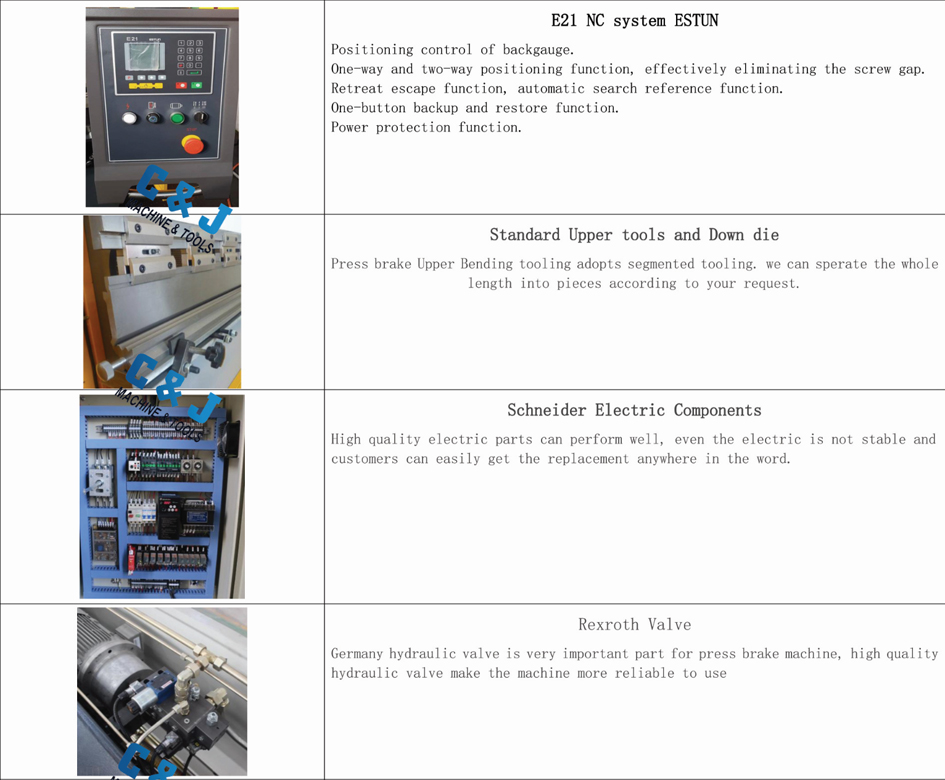

Main Configuration:

·

Holland DELEM DA66T CNC

controller

·

Grating ruler controls depth of

Y1 and Y2 axis( y1 / y2-axis 0.01mm )

·

Servo motor drive and control X

axis(X-axis 0.05mm ), manually adjusts R axis movement up and down, stopping

finger easily move along the cylindrical guide rail

·

Maintain the accuracy of HIWIN

ball screw and linear guide of 0.01mm

·

Front carrier position can be

adjusted along the linear guide rail in the worktable direction

·

Use Germany Rexroth closed-loop

electro-hydraulic servo synchronous control system

·

Germany EMB oil tube connector

·

Germany Siemens main motor

·

France Schneider Electrics

·

Hydraulic and electrical

overload protection

·

Upper are mechanical fast

pinching dies. Lower are double-V replaceable dies

2.

Safety Standard:

1.EN

12622:2009 + A1:2013 2.EN

ISO 12100:2010 3.EN 60204-1:2006+A1:2009

·

Front protection device for

protecting finger ( safe light curtain )

·

South Korea KACON Pedal switch

( 4 safety grade )

·

Rear metal safeguards and CE

standard

·

Safety relay monitors completed

with pedal switch, safety protection

·

Safety standards(2006/42/EC)

3.

Holland Delem DA66T Controller:

·

2D Touch Graphics programming,

automatically calculates the bending process and detects collision

·

3D product figure analog

display, multi-workstation dies real-time demonstrates real bending operation

·

17”high-resolution TFT color

screen

·

Full-set Windows application

package, maximize the operation stability, support instant shutdown

·

Compatible with DELEM modular

structure

·

USB Peripheral interface

·

Users application programs

under multitask condition

·

Angle-detecting sensor interface

WC67Y-125X3200 CNC Hydraulic Press Brake Machine With DA66T System

|

Model No.

|

WC67Y

25/1600

|

WC67Y

25/2000

|

WC67Y

25/2500

|

WC67Y

40/2000

|

|

|

|

|

|

|

|

Specifications

|

|

|

Normal

Pressure (Kn)

|

250 kn

|

250 kn

|

250 kn

|

400 kn

|

|

Working

Table Length(mm)

|

1600 mm

|

2000 mm

|

2500 mm

|

2000 mm

|

|

Distance

Between Housing

|

1190 mm

|

1590 mm

|

2090 mm

|

1590 mm

|

|

Throat

Depth (mm)

|

200 mm

|

200 mm

|

200 mm

|

200 mm

|

|

Side

stroke (mm)

|

100 mm

|

100 mm

|

100 mm

|

100 mm

|

|

Ma.open

height (mm)

|

300 mm

|

300 mm

|

300 mm

|

300 mm

|

|

Working

Speed

|

12 mm

|

12 mm

|

12 mm

|

8 mm

|

|

Motor

Power

|

3 kw

|

3 kw

|

3 kw

|

5.5 kw

|

|

PackingSize(cm)

|

167x127x180

|

207x127x180

|

257x127x180

|

207x127x180

|

|

Model No.

|

WC67Y

40/2500

|

WC67Y

50/2500

|

WC67Y

50/3200

|

WC67Y

63/2500

|

|

|

|

|

|

|

|

Specifications

|

|

|

Normal

Pressure (Kn)

|

400 kn

|

500 kn

|

500 kn

|

630 kn

|

|

Working

Table Length(mm)

|

2500 mm

|

2500 mm

|

3200 mm

|

2500 mm

|

|

Distance

Between Housing

|

2090 mm

|

1900 mm

|

2600 mm

|

2050 mm

|

|

Throat

Depth (mm)

|

200 mm

|

250 mm

|

250 mm

|

250 mm

|

|

Side

stroke (mm)

|

100 mm

|

120 mm

|

120 mm

|

100 mm

|

|

Ma.open

height (mm)

|

300 mm

|

300 mm

|

300 mm

|

360 mm

|

|

Working

Speed

|

8 mm

|

8 mm

|

8 mm

|

8 mm

|

|

Motor

Power

|

5.5 kw

|

5.5 kw

|

5.5 kw

|

5.5 kw

|

|

PackingSize(cm)

|

257x127x180

|

257x135x196

|

327x135x196

|

256x173x228

|

|

Model No.

|

WC67Y

63/3200

|

WC67Y

80/3200

|

WC67Y

100/3200

|

WC67Y

100/4000

|

|

|

|

|

|

|

|

Specifications

|

|

|

Normal

Pressure (Kn)

|

630 kn

|

800 kn

|

1000 kn

|

1000 kn

|

|

Working

Table Length(mm)

|

3200 mm

|

3200 mm

|

3200 mm

|

4000 mm

|

|

Distance

Between Housing

|

2600 mm

|

2600 mm

|

2600 mm

|

3200 mm

|

|

Throat

Depth (mm)

|

250 mm

|

250 mm

|

320 mm

|

320 mm

|

|

Side

stroke (mm)

|

100 mm

|

100 mm

|

130 mm

|

130 mm

|

|

Ma.open

height (mm)

|

360 mm

|

360 mm

|

390 mm

|

390 mm

|

|

Working

Speed

|

8 mm

|

8 mm

|

8 mm

|

8 mm

|

|

Motor

Power

|

5.5 kw

|

7.5 kw

|

7.5 kw

|

7.5 kw

|

|

PackingSize(cm)

|

326x173x228

|

326x181x224

|

326x125x235

|

406x125x265

|

|

Model No.

|

WC67Y

125/3200

|

WC67Y

160/3200

|

WC67Y

300/5000

|

|

|

|

|

|

|

|

|

Specifications

|

|

|

Normal

Pressure (Kn)

|

1250 kn

|

1600 kn

|

3000 kn

|

|

|

Working

Table Length(mm)

|

3200 mm

|

3200 mm

|

5000 mm

|

|

|

Distance

Between Housing

|

2600 mm

|

2600 mm

|

4080 mm

|

|

|

Throat

Depth (mm)

|

320 mm

|

320 mm

|

400 mm

|

|

|

Side

stroke (mm)

|

130 mm

|

200 mm

|

250 mm

|

|

|

Ma.open

height (mm)

|

390 mm

|

470 mm

|

560 mm

|

|

|

Working

Speed

|

8 mm

|

8 mm

|

6 mm

|

|

|

Motor

Power

|

7.5 kw

|

11 kw

|

22 kw

|

|

|

PackingSize(cm)

|

326x167x240

|

326x146x264

|

503x214x344

|

|

WC67Y-125X3200 CNC Hydraulic Press Brake Machine With DA66T System

WC67Y-125X3200 CNC Hydraulic Press Brake Machine With DA66T System

1.

Main Configuration:

·

Holland DELEM DA66T CNC

controller

·

Grating ruler controls depth of

Y1 and Y2 axis( y1 / y2-axis 0.01mm )

·

Servo motor drive and control X

axis(X-axis 0.05mm ), manually adjusts R axis movement up and down, stopping

finger easily move along the cylindrical guide rail

·

Maintain the accuracy of HIWIN

ball screw and linear guide of 0.01mm

·

Front carrier position can be

adjusted along the linear guide rail in the worktable direction

·

Use Germany Rexroth closed-loop

electro-hydraulic servo synchronous control system

·

Germany EMB oil tube connector

·

Germany Siemens main motor

·

France Schneider Electrics

·

Hydraulic and electrical

overload protection

·

Upper are mechanical fast

pinching dies. Lower are double-V replaceable dies

2.

Safety Standard:

1.EN

12622:2009 + A1:2013 2.EN

ISO 12100:2010 3.EN 60204-1:2006+A1:2009

·

Front protection device for

protecting finger ( safe light curtain )

·

South Korea KACON Pedal switch

( 4 safety grade )

·

Rear metal safeguards and CE

standard

·

Safety relay monitors completed

with pedal switch, safety protection

·

Safety standards(2006/42/EC)

3.

Holland Delem DA66T Controller:

·

2D Touch Graphics programming,

automatically calculates the bending process and detects collision

·

3D product figure analog

display, multi-workstation dies real-time demonstrates real bending operation

·

17”high-resolution TFT color

screen

·

Full-set Windows application

package, maximize the operation stability, support instant shutdown

·

Compatible with DELEM modular

structure

·

USB Peripheral interface

·

Users application programs

under multitask condition

·

Angle-detecting sensor interface