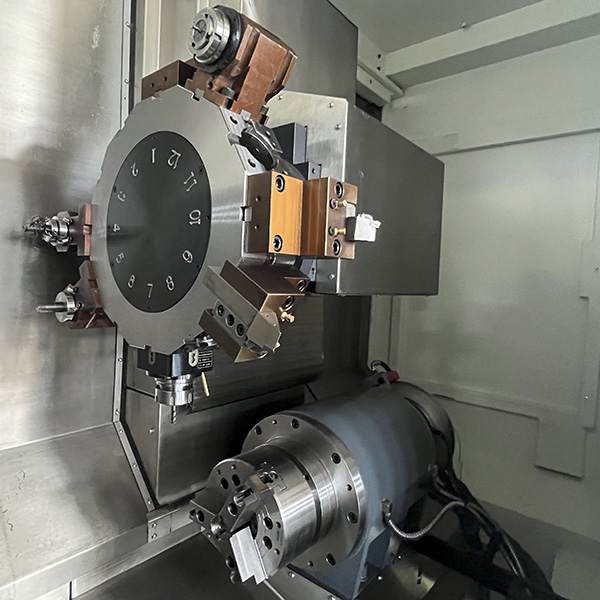

TT45 series Double-Spindle Double- Turret CNC Turning Machine

Machine Characteristics

The TT35 TT45 series CNC turning machine is an innovative machine tool product developed . Its unique modular design, simple and powerful cutting capabilities bring unlimited possibilities to your production!

1. High-precision and high-rigidity electric spindle

1.1. High-performance response characteristics (0-5000rpm fastest 0.2s)

1.2. Strong power (up to 580N.m)

1.3. Excellent processing efficiency (maximum speed up to 8000rpm)

1.4. Excellent precision performance (end face and internal and external cone runout ≤ 0.001mm)

2. High rigidity Y axis

2.1. High rigidity virtual Y-axis system + high torque and high rigidity power tool turret

2.2. Modular design, virtual Y axis interchangeable with standard model

3. Optional: high-rigidity high-speed servo turret

3.1. Excellent structure and large-size chainring make it ultra-high rigidity

3.2. Efficient processing: the tool changing time on the front/opposite side can be as low as 0.15/0.5s

4 Synchronous docking sub-spindle

4.1. High-precision and high-rigidity electric spindle: sub-spindle

4.2. Modular design, tailstock-sub-spindle can be switched at will for high-speed docking, achieving synchronous "handshake" and efficient parts interaction.

5. Optional: NC intelligent tailstock

5.1.Integral mobile programmable servo tailstock

5.2. Programmable control of thrust, position and speed: intelligent tailstock control

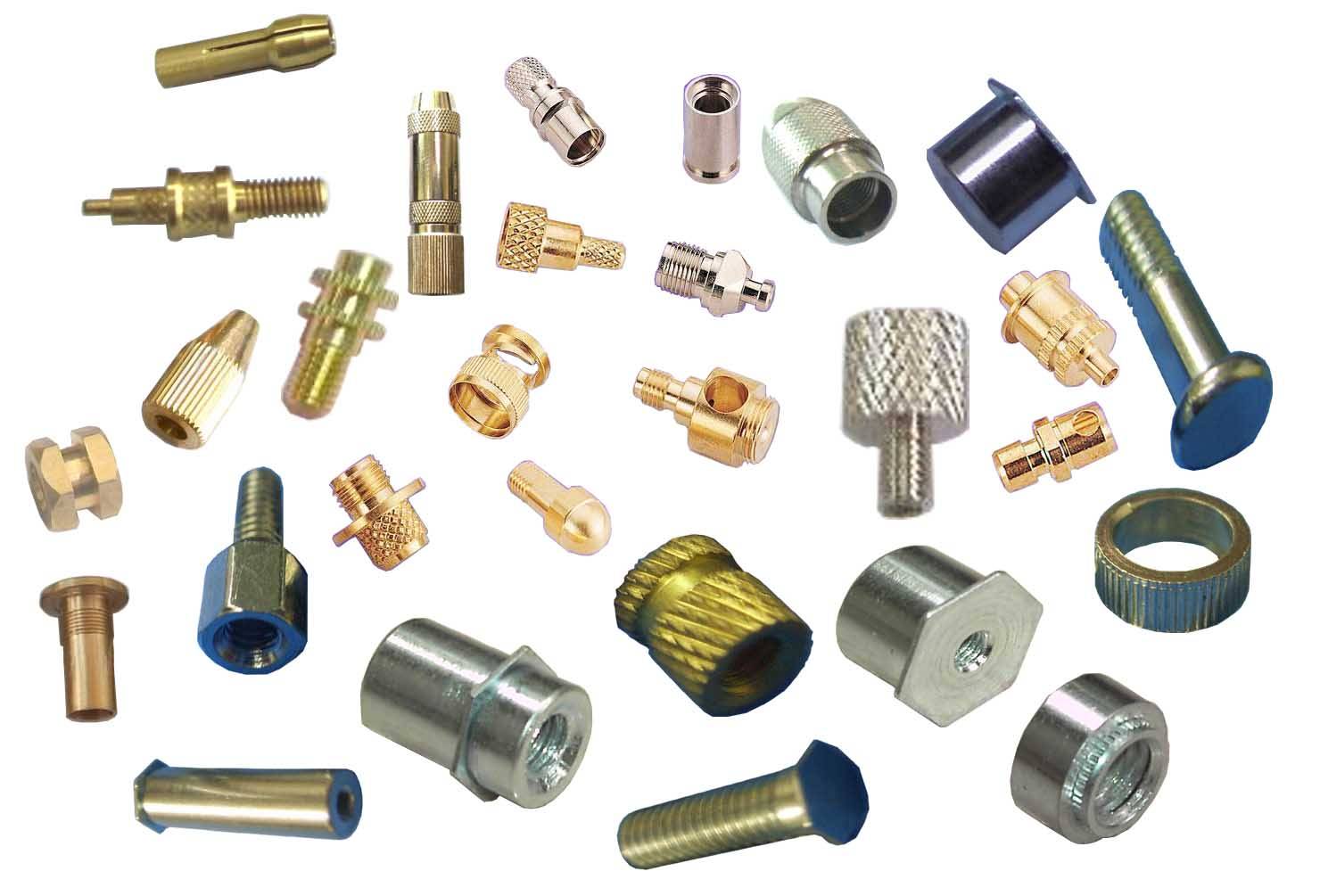

Applications

1. Shaft components: CNC lathes are capable of machining a range of shaft components such as transmission shafts, drive shafts,and crankshafts with high precision and efficiency.

2. Valve components: CNC lathes have the ability to machine valve components such as valve bodies, valve stems, and valve seats with high precision and tight tolerances.

3. Aerospace components: CNC lathes can be used to machine complex aerospace components such as engine components, landing gear components, and flight control components.

4. Electrical components: CNC lathes can be used to machine electrical components such as connectors, terminals, and conductive components with high accuracy and quality.

5. Medical components: CNC lathes can be used to create precise medical components such as surgical instruments, dental implants, and prosthetics.

6. Automotive components: CNC lathes are widely used in the automotive industry to manufacture components such as bearings,axles, and gears.

7. Hydraulic components: CNC lathes are capable of producing high-precision hydraulic components such as cylinders, pistons, and pump parts.

8. Mold components: CNC lathes are commonly used to produce mold components such as core pins, ejector pins, and cavity inserts with precision and efficiency.

9. Precision gears: CNC lathes are ideal for manufacturing precision gears such as spur gears, helical gears, and bevel gears with high accuracy and repeatability.

10. Sports equipment components: CNC lathes can be used to manufacture a variety of sports equipment components such as golf club heads, bicycle parts, and fishing reels.

Processing Case

TT45 series Double-Spindle Double- Turret CNC Turning Machine

|

model

|

TT35Series

|

TT45Series

|

|

Spindle taper (main/auxiliary)(jis)

|

A2-5/A2-5

|

A2-6/A2-6

|

|

Standard chuck size (main/auxiliary)

|

6/6

|

8/8

|

|

Max spindle speed (main/auxiliary)(rpm)

|

6000/6000

|

4500/4500

|

|

Spindle power (main/auxiliary)(kw)

|

11/11

|

15/15

|

|

Max processing diameter(mm)

|

Φ250

|

Φ300

|

|

Max processing length(mm)

|

200

|

250

|

|

Number of tools12/15(pcs)

|

12/15

|

12/15

|

|

Tool specifications(mm)

|

25/Φ32

|

25/Φ40

|

|

Powered tool holder specifications

|

BMT45

|

BMT55

|

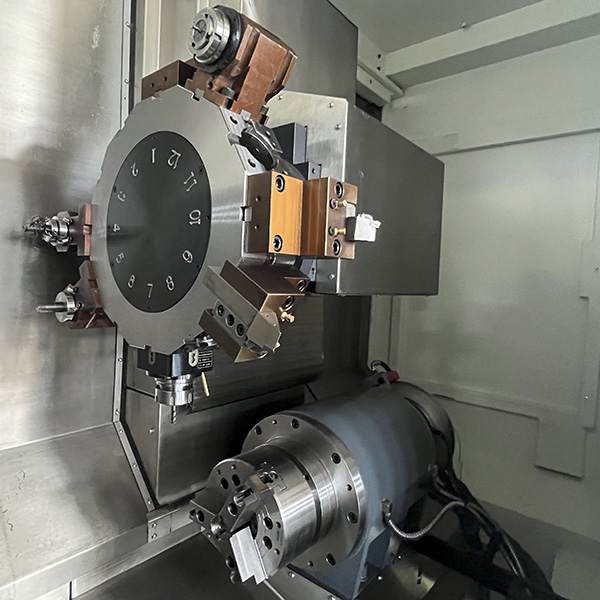

TT45 series Double-Spindle Double- Turret CNC Turning Machine

Machine Characteristics

The TT35 TT45 series CNC turning machine is an innovative machine tool product developed . Its unique modular design, simple and powerful cutting capabilities bring unlimited possibilities to your production!

1. High-precision and high-rigidity electric spindle

1.1. High-performance response characteristics (0-5000rpm fastest 0.2s)

1.2. Strong power (up to 580N.m)

1.3. Excellent processing efficiency (maximum speed up to 8000rpm)

1.4. Excellent precision performance (end face and internal and external cone runout ≤ 0.001mm)

2. High rigidity Y axis

2.1. High rigidity virtual Y-axis system + high torque and high rigidity power tool turret

2.2. Modular design, virtual Y axis interchangeable with standard model

3. Optional: high-rigidity high-speed servo turret

3.1. Excellent structure and large-size chainring make it ultra-high rigidity

3.2. Efficient processing: the tool changing time on the front/opposite side can be as low as 0.15/0.5s

4 Synchronous docking sub-spindle

4.1. High-precision and high-rigidity electric spindle: sub-spindle

4.2. Modular design, tailstock-sub-spindle can be switched at will for high-speed docking, achieving synchronous "handshake" and efficient parts interaction.

5. Optional: NC intelligent tailstock

5.1.Integral mobile programmable servo tailstock

5.2. Programmable control of thrust, position and speed: intelligent tailstock control

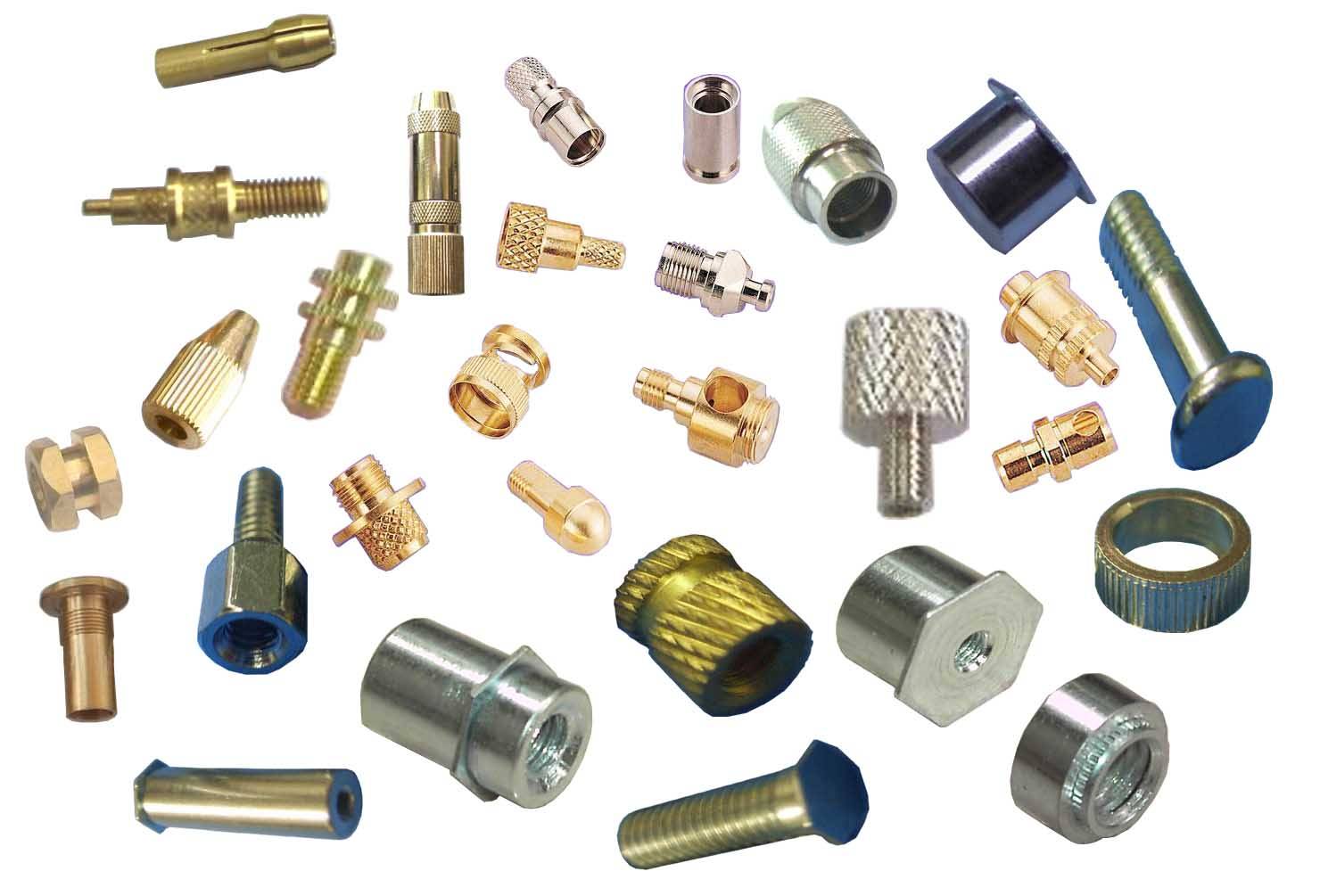

Applications

1. Shaft components: CNC lathes are capable of machining a range of shaft components such as transmission shafts, drive shafts,and crankshafts with high precision and efficiency.

2. Valve components: CNC lathes have the ability to machine valve components such as valve bodies, valve stems, and valve seats with high precision and tight tolerances.

3. Aerospace components: CNC lathes can be used to machine complex aerospace components such as engine components, landing gear components, and flight control components.

4. Electrical components: CNC lathes can be used to machine electrical components such as connectors, terminals, and conductive components with high accuracy and quality.

5. Medical components: CNC lathes can be used to create precise medical components such as surgical instruments, dental implants, and prosthetics.

6. Automotive components: CNC lathes are widely used in the automotive industry to manufacture components such as bearings,axles, and gears.

7. Hydraulic components: CNC lathes are capable of producing high-precision hydraulic components such as cylinders, pistons, and pump parts.

8. Mold components: CNC lathes are commonly used to produce mold components such as core pins, ejector pins, and cavity inserts with precision and efficiency.

9. Precision gears: CNC lathes are ideal for manufacturing precision gears such as spur gears, helical gears, and bevel gears with high accuracy and repeatability.

10. Sports equipment components: CNC lathes can be used to manufacture a variety of sports equipment components such as golf club heads, bicycle parts, and fishing reels.

Processing Case

TT45 series Double-Spindle Double- Turret CNC Turning Machine

|

model

|

TT35Series

|

TT45Series

|

|

Spindle taper (main/auxiliary)(jis)

|

A2-5/A2-5

|

A2-6/A2-6

|

|

Standard chuck size (main/auxiliary)

|

6/6

|

8/8

|

|

Max spindle speed (main/auxiliary)(rpm)

|

6000/6000

|

4500/4500

|

|

Spindle power (main/auxiliary)(kw)

|

11/11

|

15/15

|

|

Max processing diameter(mm)

|

Φ250

|

Φ300

|

|

Max processing length(mm)

|

200

|

250

|

|

Number of tools12/15(pcs)

|

12/15

|

12/15

|

|

Tool specifications(mm)

|

25/Φ32

|

25/Φ40

|

|

Powered tool holder specifications

|

BMT45

|

BMT55

|