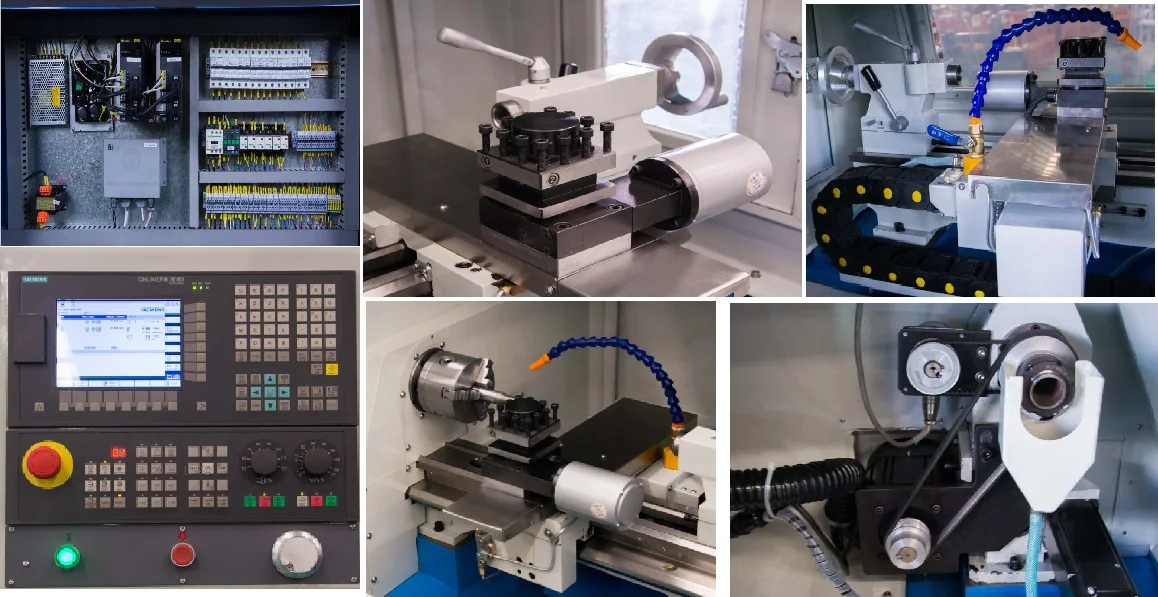

Machine details:

Product features:

1. A CNC lathe for all types of cutting. It can be used for turning the outer circle, end face, drilling, boring and thread turning. Precision parts processing, sample processing and processing models can also be used.

2. Widely used, simple to operate, and widely processed. High-frequency quenching process and high-quality cast iron bed precision grinding.

3. CNC system: Guangshu system, Siemens system optional

Main features:

1.This high precision small cnc lathe can process precisely internal or external diameter, face, taper, arc and threading with high efficiency

2.Standard toolpost is 4 stations

3.high precision small cnc lathe with Spindle speed changed by frequency

4.Induction harden bed way, bed saddle with plastic sticker can improve the accuracy and service life of the machine

5.The spindle of China high precision mini cnc lathe machine is supported by imported precision bearing.

6.Normally machine is provide with 3 jaw chuck. According to customer’s optional selection, hydraulic chuck or pneumatic chuck also can be supplied with China high precision mini cnc lathe machine.

1)The high precision small cnc lathe can process precisely internal or external diameter, face, taper and threading with high efficiency.

2)DC brushless spindle motor.

3)Induction harden bed-way. Bed saddle with plastic sticker can improve the accuracy and service life of thehigh precision small cnc lathe.

4)Macro arithmetic operations can be performed, the processing of complex parts, fully functional, economical and practical, with a textbook for teaching.

CK210 CNC Mini lathe

|

Swing over bed

|

210mm

|

|

Distance between centers

|

400mm

|

|

Spindle aperture

|

26mm

|

|

Spindle taper

|

MT4

|

|

Spindle speed

|

50-2500rpm

|

|

Tool post

|

4-position

|

|

X-axis stroke

|

80mm

|

|

Z-axis travel

|

300mm

|

|

X-axis fast moving speed

|

2000mm/min

|

|

Z-axis fast moving speed

|

2000mm/min

|

|

Spindle motor power

|

1.2kw

|

|

X-axis motor torque

|

2N.m

|

|

Z-axis motor torque

|

2N.m

|

|

Minimum setting unit

|

0.001mm

|

|

Repetitive positioning accuracy

|

0.01mm

|

|

Repetitive positioning accuracy

|

0.02mm

|

|

Accuracy level of screw rod

|

P4

|

|

Tail socket diameter

|

22mm

|

|

Short stroke of tail seat cover

|

50mm

|

|

Tailstock sleeve taper

|

MT2

|

|

Overall size

|

1170X700X860mm

1170*700*1300mm (+Stand)

|

|

N.W

|

200kg

340KG(+ stand)

|

Standard accessories

1.3-jaw chuck and wrench

2.Allen wrench

3.Electrical tool post 4 station

4.Cooling system

5.Manual lubricating system

6.Working lamp

7.Siemens CNC controller system

8.Steel stand

Optional accessories

1.Pneumatic chuck

2.Hydraulic chuck

3.Controller system GSK, Fanuc

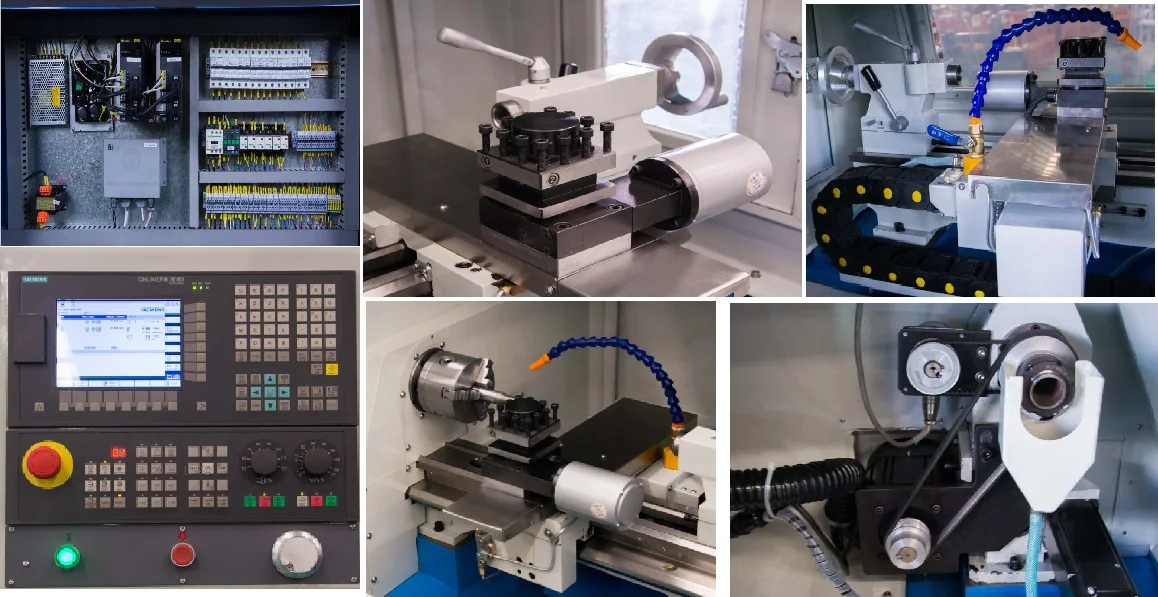

Machine details:

Product features:

1. A CNC lathe for all types of cutting. It can be used for turning the outer circle, end face, drilling, boring and thread turning. Precision parts processing, sample processing and processing models can also be used.

2. Widely used, simple to operate, and widely processed. High-frequency quenching process and high-quality cast iron bed precision grinding.

3. CNC system: Guangshu system, Siemens system optional

Main features:

1.This high precision small cnc lathe can process precisely internal or external diameter, face, taper, arc and threading with high efficiency

2.Standard toolpost is 4 stations

3.high precision small cnc lathe with Spindle speed changed by frequency

4.Induction harden bed way, bed saddle with plastic sticker can improve the accuracy and service life of the machine

5.The spindle of China high precision mini cnc lathe machine is supported by imported precision bearing.

6.Normally machine is provide with 3 jaw chuck. According to customer’s optional selection, hydraulic chuck or pneumatic chuck also can be supplied with China high precision mini cnc lathe machine.

1)The high precision small cnc lathe can process precisely internal or external diameter, face, taper and threading with high efficiency.

2)DC brushless spindle motor.

3)Induction harden bed-way. Bed saddle with plastic sticker can improve the accuracy and service life of thehigh precision small cnc lathe.

4)Macro arithmetic operations can be performed, the processing of complex parts, fully functional, economical and practical, with a textbook for teaching.

Standard accessories

1.3-jaw chuck and wrench

2.Allen wrench

3.Electrical tool post 4 station

4.Cooling system

5.Manual lubricating system

6.Working lamp

7.Siemens CNC controller system

8.Steel stand

Optional accessories

1.Pneumatic chuck

2.Hydraulic chuck

3.Controller system GSK, Fanuc