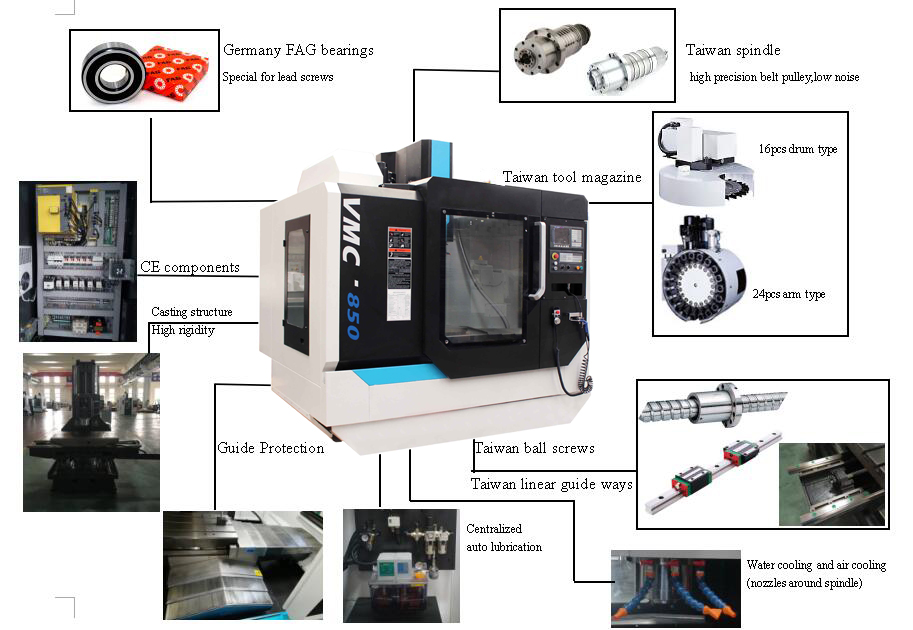

CNC Machining center Features:

1.Bed body, worktable, slide, column, headstock, etc are made up by high rigidity cast iron material

2.X/Y/Z-axis adopts Taiwan HIWIN linear guide ways( width 45mm )

3.X/Y/Z-axis servo motor connects Taiwan HIWIN high precision ball screws through one elastic coupling respectively

4.Z-axis servo motor is with automatic self-braking function

5.Taiwan POSA brand spindle unit with 8000rpm,the max. spindle speed can be achieved to 6000rpm. NSK bearing for spindle with P4 grade

6.Taiwan brand umbrella type tool magazine

7.Equipped with large flow cooling pump and large capacity water tank, fully ensure the cooling, the power of the cooling pump is 120W ,20L/min, high pressure punching and provide the full cooling.

8.There is also cooling jet at the top surface of spindle box, which can be either water cooling or air cooling, and can be changed easily

9.Pneumatic triple can filter impurities and moisture in the gas source, to prevent the damage and corrosion of the machine parts by the impure gas. Electromagnetic valve group by PLC program control, ensure that the spindle loose tools, spindle center blowing, spindle folder tools, air cooling spindle etc. actions can be completed quickly and accurately.

10.centralized automatic lubrication,

|

SPECIFICAITONS:

|

UNIT

|

VMC850

|

|

Worktable

|

Table size

|

mm

|

1000x500

|

|

T slot(number/width/distance of T-slot)

|

mm

|

5-18-100

|

|

Centre distance

|

mm

|

100

|

|

T-Width

|

mm

|

18

|

|

Max. load of worktable

|

kg

|

500

|

|

Machining range

|

Longitudinal travel

|

mm

|

850

|

|

Cross travel

|

mm

|

500

|

|

Vertical travel

|

mm

|

500

|

|

Spindle

|

Spindle nose to table surface

|

mm

|

110-610

|

|

Spidle axis to column surface

|

mm

|

560

|

|

Spindle taper

|

--

|

BT40

|

|

Speed Range

|

rpm

|

40-6000

|

|

Max.spindle torque

|

N.M

|

26.3

|

|

Motor

|

Spindle motor power

|

kw

|

7.5

|

|

Feed motor (X/Y/Z)

|

KW

|

1.8

|

|

Feed

|

Cuttiing feed X/Y/Z

|

mm / min

|

10-10000

|

|

Rapid feed X/Y/Z

|

m / min

|

30/30/24

|

|

Tool magazine

|

Tool magazine capacity

|

piece

|

16

|

|

Tool magazine type

|

--

|

Carousel

|

|

Max. tool dimension

|

mm

|

130x250

|

|

Max. tool weight

|

kg

|

8

|

|

Tool changing time (tip to tip)

|

s

|

3

|

|

Accuracy

|

Positioning accuracy

|

mm

|

±0.005/300

|

|

Repeat positioning accuracy

|

mm

|

±0.003/300

|

|

Others

|

Air pressure

|

Mpa

|

5---6

|

|

Overall dimension

|

mm

|

2500x2360x2300

|

|

Machine weight

|

kg

|

4750

|

|

Packing list

|

|

|

|

Name

|

Specification

|

Qty

|

Remark

|

|

Machine

|

VMC850

|

1

|

|

|

Adjusting sizing block

|

|

8 sets

|

|

|

Inner hexagon spanner

|

5,6,8,10

|

Each 1

|

|

|

Wrench

|

S17~19

|

Each 1

|

|

|

S22~24

|

|

Foundation bolts

|

M16×450

|

8 pieces

|

|

|

Hex. nut

|

M16

|

8 pieces

|

|

|

Washer

|

16

|

8 pieces

|

|

|

CNC system

|

|

1set

|

With machine

|

|

Operation manual

|

|

1set

|

|

|

Packing list

|

|

1

|

|

Standard Accessories:

1)16 Tools magazine from Taiwan.

2)BT40 spindle unit with 8000rpm spindle unit

3)X,Y,Z—axis with Linear guide way from HI-WIN

4) Full protection

5)Halogen work light

6) Coolant

7)Electric Hand wheel

8)Centralized auto-lubrication system

9) GSK25i system

Optional Accessories:

1)Electro-magnetic door clock.

2)Round type Tool magazine with 24 tools

3)The 4—axis, (Rotary worktable or dividing Head)

4)Spindle unit with Oil coolant and 10000 rpm speed.

5)Chain type chip conveyor

6)FANUC 0i MD or SIEMENS 828DCNC system

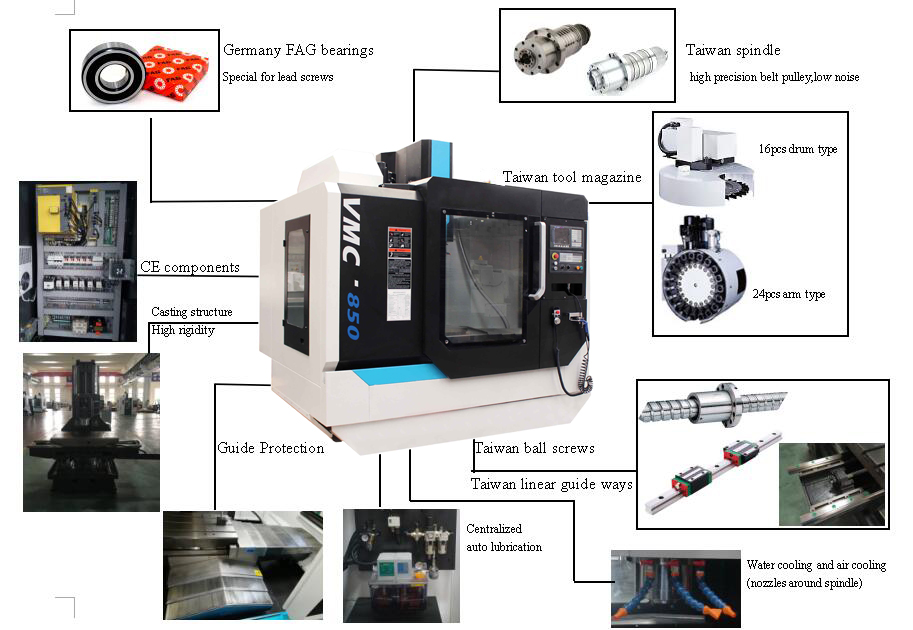

CNC Machining center Features:

1.Bed body, worktable, slide, column, headstock, etc are made up by high rigidity cast iron material

2.X/Y/Z-axis adopts Taiwan HIWIN linear guide ways( width 45mm )

3.X/Y/Z-axis servo motor connects Taiwan HIWIN high precision ball screws through one elastic coupling respectively

4.Z-axis servo motor is with automatic self-braking function

5.Taiwan POSA brand spindle unit with 8000rpm,the max. spindle speed can be achieved to 6000rpm. NSK bearing for spindle with P4 grade

6.Taiwan brand umbrella type tool magazine

7.Equipped with large flow cooling pump and large capacity water tank, fully ensure the cooling, the power of the cooling pump is 120W ,20L/min, high pressure punching and provide the full cooling.

8.There is also cooling jet at the top surface of spindle box, which can be either water cooling or air cooling, and can be changed easily

9.Pneumatic triple can filter impurities and moisture in the gas source, to prevent the damage and corrosion of the machine parts by the impure gas. Electromagnetic valve group by PLC program control, ensure that the spindle loose tools, spindle center blowing, spindle folder tools, air cooling spindle etc. actions can be completed quickly and accurately.

10.centralized automatic lubrication,

|

SPECIFICAITONS:

|

UNIT

|

VMC850

|

|

Worktable

|

Table size

|

mm

|

1000x500

|

|

T slot(number/width/distance of T-slot)

|

mm

|

5-18-100

|

|

Centre distance

|

mm

|

100

|

|

T-Width

|

mm

|

18

|

|

Max. load of worktable

|

kg

|

500

|

|

Machining range

|

Longitudinal travel

|

mm

|

850

|

|

Cross travel

|

mm

|

500

|

|

Vertical travel

|

mm

|

500

|

|

Spindle

|

Spindle nose to table surface

|

mm

|

110-610

|

|

Spidle axis to column surface

|

mm

|

560

|

|

Spindle taper

|

--

|

BT40

|

|

Speed Range

|

rpm

|

40-6000

|

|

Max.spindle torque

|

N.M

|

26.3

|

|

Motor

|

Spindle motor power

|

kw

|

7.5

|

|

Feed motor (X/Y/Z)

|

KW

|

1.8

|

|

Feed

|

Cuttiing feed X/Y/Z

|

mm / min

|

10-10000

|

|

Rapid feed X/Y/Z

|

m / min

|

30/30/24

|

|

Tool magazine

|

Tool magazine capacity

|

piece

|

16

|

|

Tool magazine type

|

--

|

Carousel

|

|

Max. tool dimension

|

mm

|

130x250

|

|

Max. tool weight

|

kg

|

8

|

|

Tool changing time (tip to tip)

|

s

|

3

|

|

Accuracy

|

Positioning accuracy

|

mm

|

±0.005/300

|

|

Repeat positioning accuracy

|

mm

|

±0.003/300

|

|

Others

|

Air pressure

|

Mpa

|

5---6

|

|

Overall dimension

|

mm

|

2500x2360x2300

|

|

Machine weight

|

kg

|

4750

|

|

Packing list

|

|

|

|

Name

|

Specification

|

Qty

|

Remark

|

|

Machine

|

VMC850

|

1

|

|

|

Adjusting sizing block

|

|

8 sets

|

|

|

Inner hexagon spanner

|

5,6,8,10

|

Each 1

|

|

|

Wrench

|

S17~19

|

Each 1

|

|

|

S22~24

|

|

Foundation bolts

|

M16×450

|

8 pieces

|

|

|

Hex. nut

|

M16

|

8 pieces

|

|

|

Washer

|

16

|

8 pieces

|

|

|

CNC system

|

|

1set

|

With machine

|

|

Operation manual

|

|

1set

|

|

|

Packing list

|

|

1

|

|

Standard Accessories:

1)16 Tools magazine from Taiwan.

2)BT40 spindle unit with 8000rpm spindle unit

3)X,Y,Z—axis with Linear guide way from HI-WIN

4) Full protection

5)Halogen work light

6) Coolant

7)Electric Hand wheel

8)Centralized auto-lubrication system

9) GSK25i system

Optional Accessories:

1)Electro-magnetic door clock.

2)Round type Tool magazine with 24 tools

3)The 4—axis, (Rotary worktable or dividing Head)

4)Spindle unit with Oil coolant and 10000 rpm speed.

5)Chain type chip conveyor

6)FANUC 0i MD or SIEMENS 828DCNC system

|