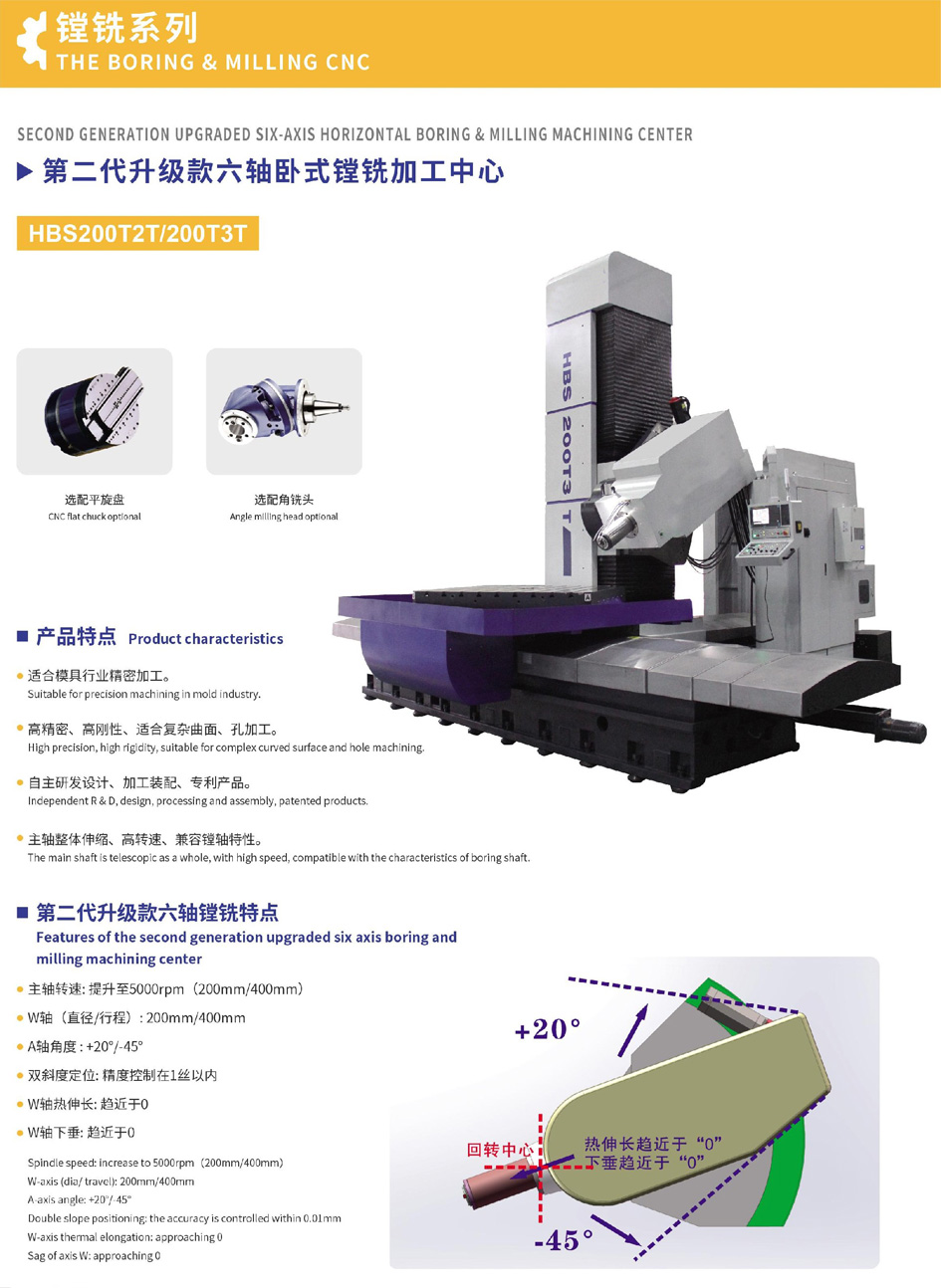

HBS200T2T/200T3T Six Axis Horizontal Boring & Milling Machining Center

Product characteristics

Suitable for precision machining in mold industry

High precision, high rigidity, suitable for complex curved surface and hole machining.

The main shaft is telescopic as a whole, with high speed, compatible with the characteristics of boring shaft

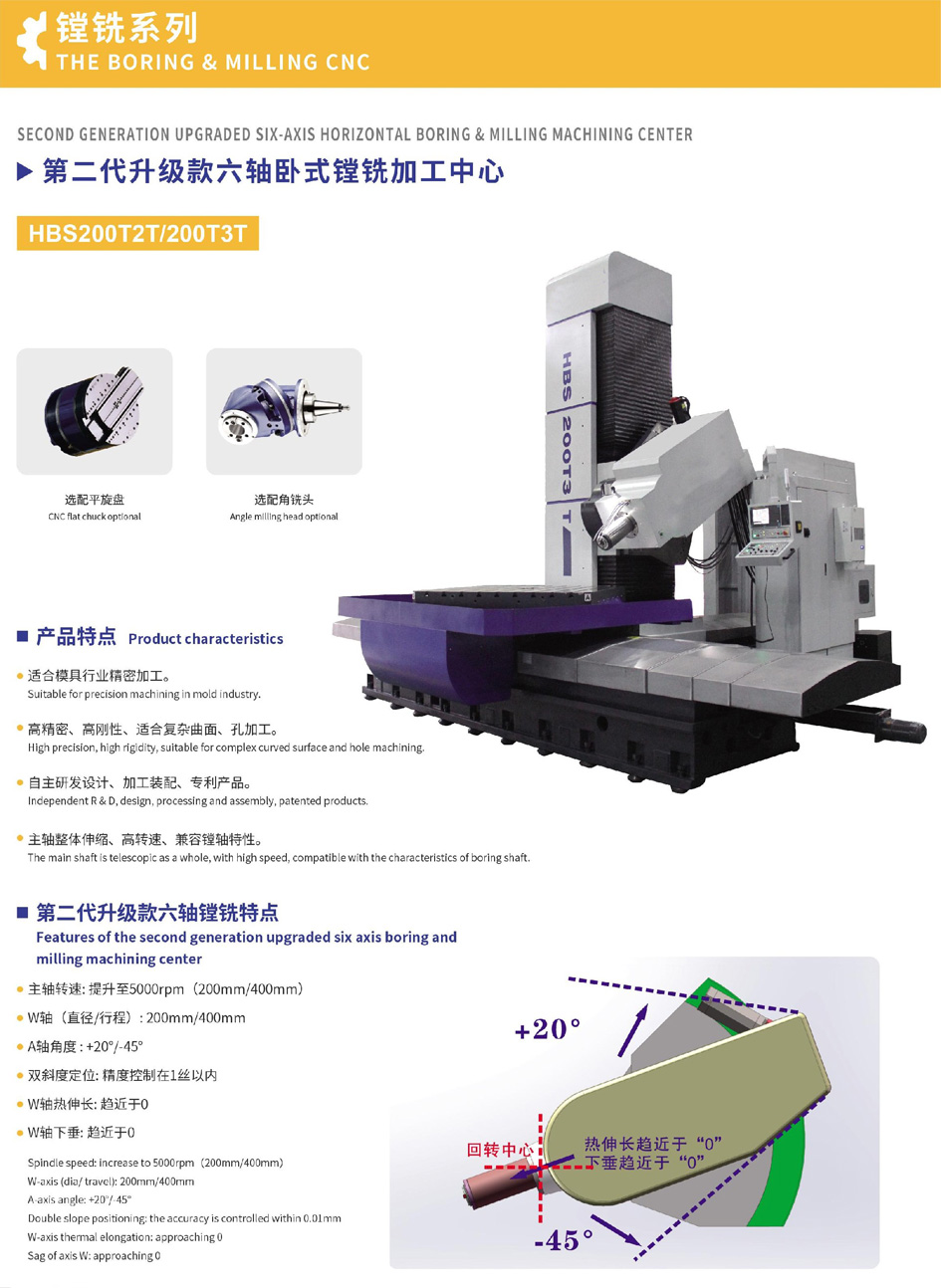

Features of the second generation upgraded six axis boring and milling machining center

Spindle speed: increase to 5000rpm(200mm/400mm)W-axis (dia/ travel): 200mm/400mm

A-axis angle: +20°/-45°

Double slope positioning: the accuracyis controlled within 0.0lmm

W-axis thermal elongation: approaching 0Sag of axis W: approaching0

HBS200T2T/200T3T Six Axis Horizontal Boring & Milling Machining Center

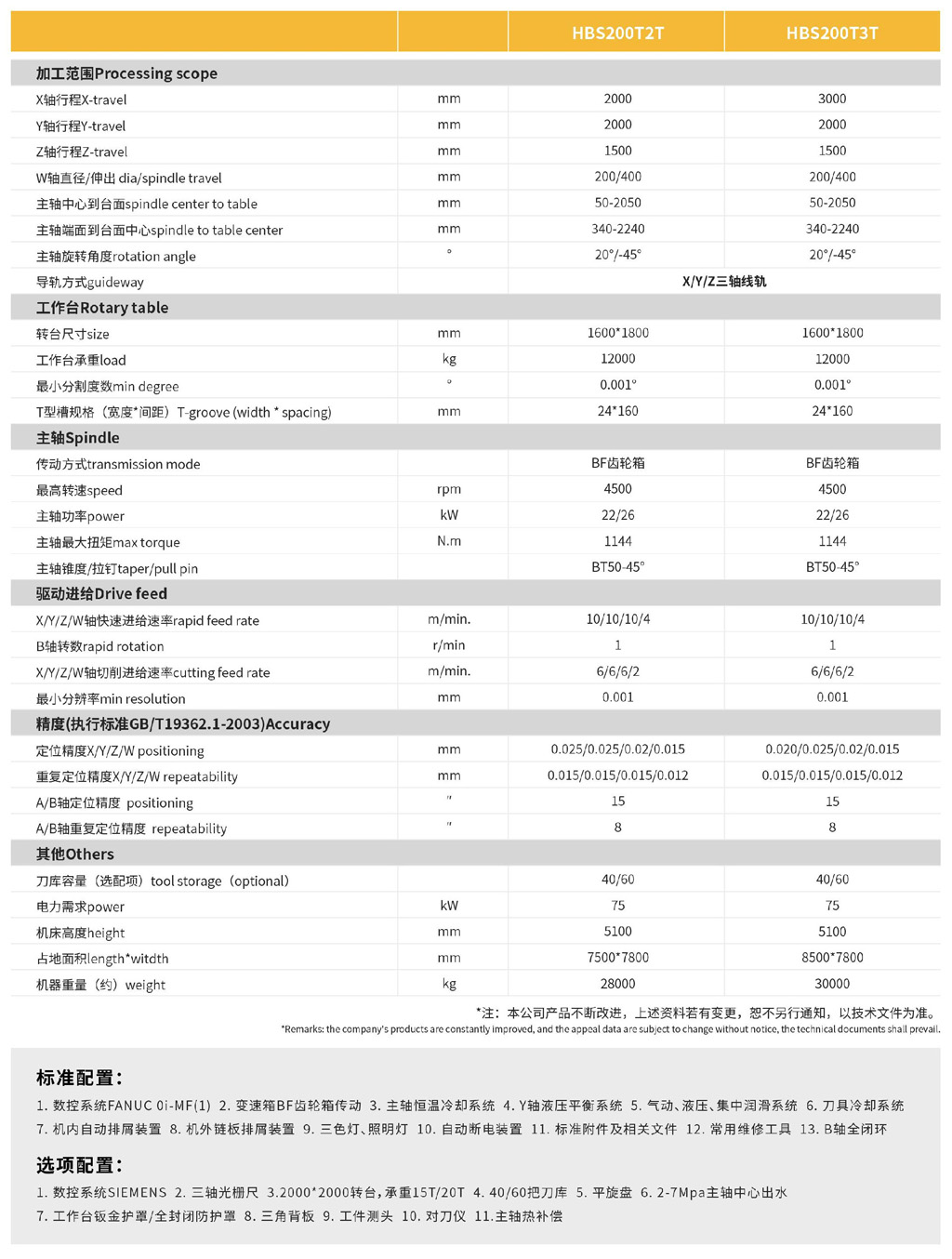

Standard accessories

1. CNC system FANUC Oi-MF (1)

2. Gearbox transmission

3. Spindle constant temperature cooling system

4. Y-axis hydraulic balance system

5. Pneumatic, hydraulic, centralized lubrication system

6. Tool cooling system

7. Automatic chip removal device inside the machine

8. Chain plate chip removal device outside the machine

9. Three-color light, lighting lamp

10. Automatic power off device

11. B axis full closed loop

Optional accessories:

1. CNC system SIEMENS

2. Three-axis grating ruler (FAGOR)

3. 40/60 tool magazine

4. Flat rotary table

5. 2-7Mpa spindle center water outlet,

6. Worktable sheet metal cover/fully enclosed protective cover

7. Triangular back plate

8. Workpiece probe

9. Tool setting instrument

10. Spindle thermal compensation

11. 2000*2000 turntable, load-bearing 15T/20

HBS200T2T/200T3T Six Axis Horizontal Boring & Milling Machining Center

Product characteristics

Suitable for precision machining in mold industry

High precision, high rigidity, suitable for complex curved surface and hole machining.

The main shaft is telescopic as a whole, with high speed, compatible with the characteristics of boring shaft

Features of the second generation upgraded six axis boring and milling machining center

Spindle speed: increase to 5000rpm(200mm/400mm)W-axis (dia/ travel): 200mm/400mm

A-axis angle: +20°/-45°

Double slope positioning: the accuracyis controlled within 0.0lmm

W-axis thermal elongation: approaching 0Sag of axis W: approaching0