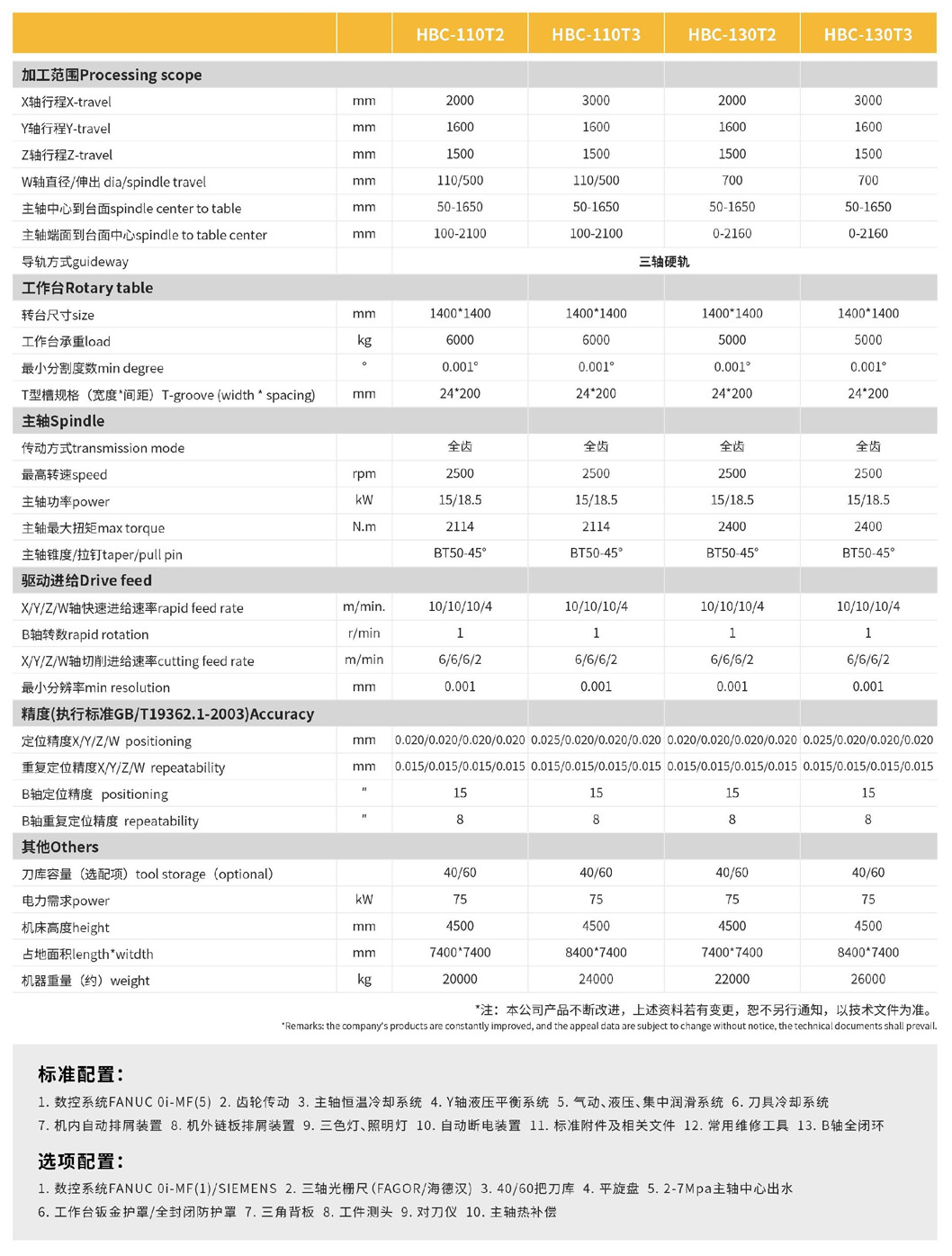

HBC-110T2/110T3/130T2/130T3 Five axis horizontal boring & milling machining center

Head

The boring shaft is made of SACMA-645, which is imported from Germany, After nitrogen treatment, thehardness is as high as (HS 100''''+ 10%), and after ultra deep cooling (- 190 ''''c) aging treatment, the expansiorwear resistance is improved;, the main shaft can be extended to 500/700mm long, suitable for deep holprocessing

Column( patented structure)

The high strength arch bridge type auxiliary structure is adopted in the high-quality Meehanite cast iron bodywhich can improve the rigidity of the column by 27%. Two times of electric furnace aging and two times ovibration aging can ensure the long-term anti-seismic deformation

Rotarytable( patentedstructure)

Adopting the hydraulic pressure design of full area support, the unique double turbine drives six tighteningforces at any angle without backlash up to 13500kg/cm? and the cylinder is locked with 90 degree bolpositioning.

HBC-110T2/110T3/130T2/130T3 Five axis horizontal boring & milling machining center

Standard accessories

1. CNC system FANUC Oi-MF (5)

2. Gearbox transmission

3. Spindle constant temperature cooling system

4. Y-axis hydraulic balance system

5. Pneumatic, hydraulic, centralized lubrication system

6. Tool cooling system

7. Automatic chip removal device inside the machine

8. Chain plate chip removal device outside the machine

9. Three-color light, lighting lamp

10. Automatic power off device

11. B-axis full closed loop

Optional accessories:

1. CNC system SIEMENS

2. Three-axis grating ruler (FAGOR)

3. 40/60 tool magazine

4. Flat rotary table

5. 2-7Mpa spindle center water outlet,

6. Worktable sheet metal cover/fully enclosed protective cover

7. Triangular back plate

8. Workpiece probe

9. Tool setting instrument

10. Spindle thermal compensation

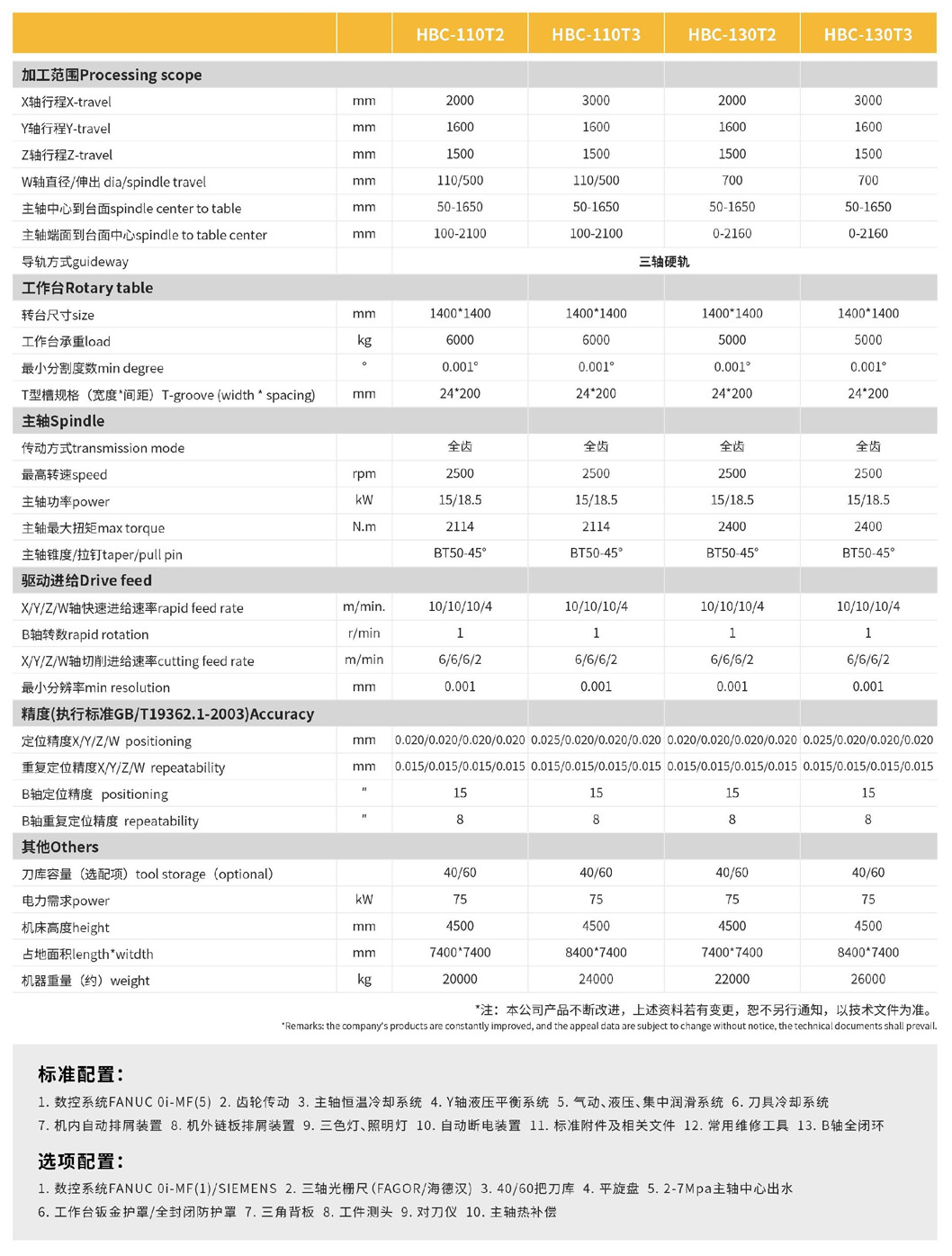

HBC-110T2/110T3/130T2/130T3 Five axis horizontal boring & milling machining center

Head

The boring shaft is made of SACMA-645, which is imported from Germany, After nitrogen treatment, thehardness is as high as (HS 100''''+ 10%), and after ultra deep cooling (- 190 ''''c) aging treatment, the expansiorwear resistance is improved;, the main shaft can be extended to 500/700mm long, suitable for deep holprocessing

Column( patented structure)

The high strength arch bridge type auxiliary structure is adopted in the high-quality Meehanite cast iron bodywhich can improve the rigidity of the column by 27%. Two times of electric furnace aging and two times ovibration aging can ensure the long-term anti-seismic deformation

Rotarytable( patentedstructure)

Adopting the hydraulic pressure design of full area support, the unique double turbine drives six tighteningforces at any angle without backlash up to 13500kg/cm? and the cylinder is locked with 90 degree bolpositioning.

HBC-110T2/110T3/130T2/130T3 Five axis horizontal boring & milling machining center

Standard accessories

1. CNC system FANUC Oi-MF (5)

2. Gearbox transmission

3. Spindle constant temperature cooling system

4. Y-axis hydraulic balance system

5. Pneumatic, hydraulic, centralized lubrication system

6. Tool cooling system

7. Automatic chip removal device inside the machine

8. Chain plate chip removal device outside the machine

9. Three-color light, lighting lamp

10. Automatic power off device

11. B-axis full closed loop

Optional accessories:

1. CNC system SIEMENS

2. Three-axis grating ruler (FAGOR)

3. 40/60 tool magazine

4. Flat rotary table

5. 2-7Mpa spindle center water outlet,

6. Worktable sheet metal cover/fully enclosed protective cover

7. Triangular back plate

8. Workpiece probe

9. Tool setting instrument

10. Spindle thermal compensation

|