TPX6113 TPX6113/2

PRODUCT FEATURES

The TPX series horizontal milling and boring machines are based ona classic design, suitable for rough and finished boring, capable ofmilling large and box type components. They excel at inner hold boringcylindrical turning and grooving by radial feed of facing plate. A 4x90optical positioning device allows for machining accuracy when turninglarge pieces. The precision digital read out measurement systemsensures accuracy of coordinates and lineation.

* Machine bed with larger specifications is added with integral auxiliary guideway

* Spindle system consists of three-layer structure, facing head spindle, hollow spindle and boring spindle

* The spindle with disk spring clamping and hydraulic unclamping makes tool handling easy

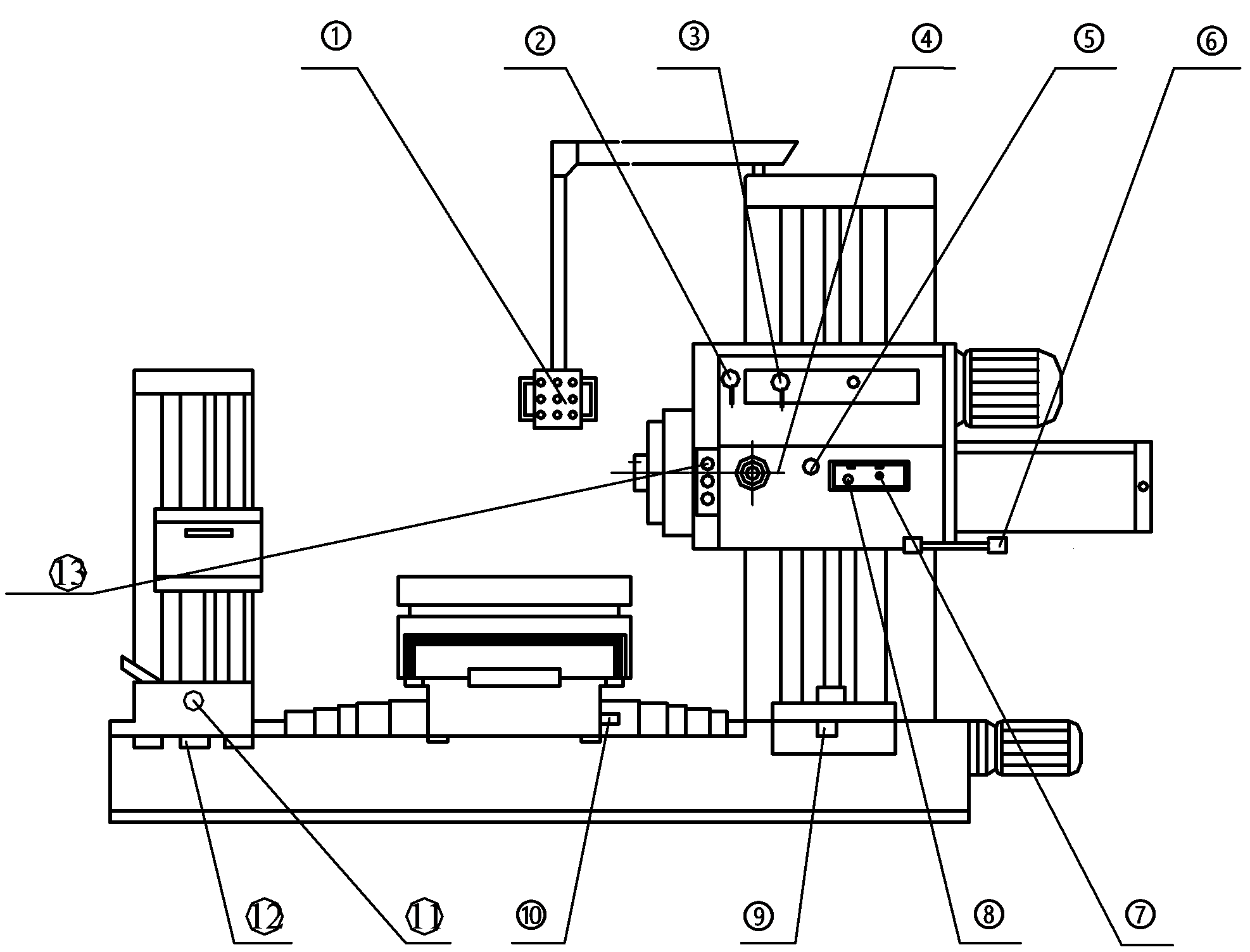

No. Name of the operation mechanism

1 Button station

2 Lever for engaging and disengaging of the facing head rotation

3 Lever for forward and reverse feed

4 Distributing lever of auto,micro and spindle feed(including radial slide)

<br /> 5 Distributing lever for the movement of spindle or radial slide on the facing head

6 Clamping lever of spindle

7 Rotating valve lever for the main movement speed change

8 Rotating lever for feed rate change

9 Lever hole for hand rough elevation of headstock

10 Lever hole for hand-driven rotation and longitudinal and cross movements of table

11 Lever hole for hand-driven longitudinal traverse and elevation of rear column

12 Clamping points of rear column (each points at back and front)

13 Distribution lever for longitudinal transverse of boring stay and elevation of boring stay slide

14 Emergency stop button(for 7:24 50#)

15 Tool unclamping button (for 7:24 50#)

16 Tool clamping button (for 7:24 50#)

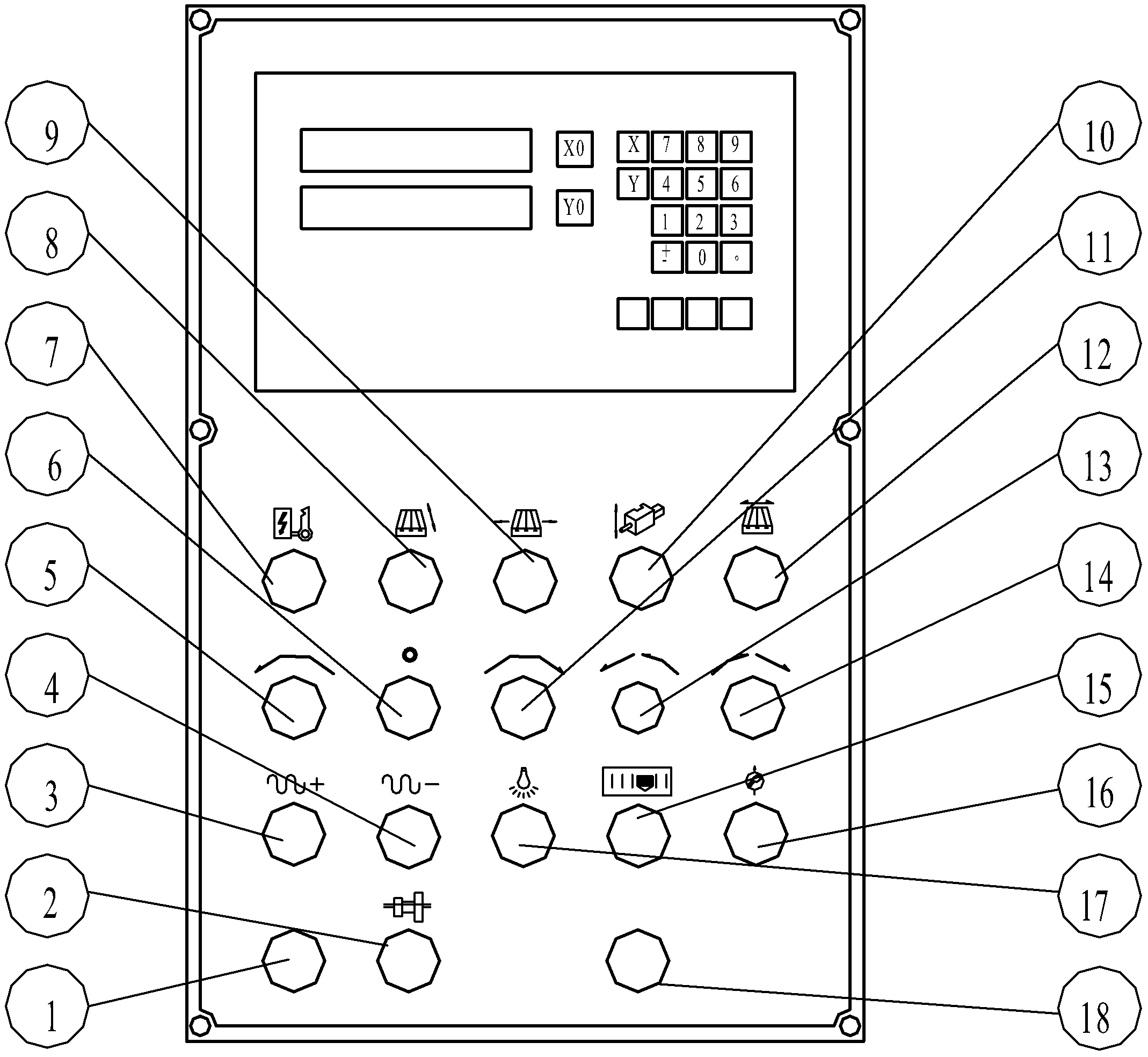

No. Description

1 Power supply indicator

2 Button for executing speed change

3 Forward rapid button

4 Reverse rapid button

5 Button for spindle or facing head rotating positively

6 Button for stopping main motor

7 Key switch

8 Button for transverse movement of table(with indicator)

9 Button for longitudinal movement of table(with indicator)

10 Button for lifting movement of headstock(with indicator)

11 Button for spindle or facing head rotating negtively

12 Button for rotation of table(with indicator)

13 Button for forward inching of spindle or facing head

14 Button for reverse inching of spindle or facing head

15 Button for optical illumination

16 Push-button for lubrication guideways

17 Switch for illuminating lamp

18 Emergency stop button

TPX6113 TPX6113/2

|

Model

|

TPX6113B

|

TPX6113B/2

|

|

Spindle Dia.(mm)

|

130

|

130

|

|

Max.Spindle torque (NM)

|

2950

|

2950

|

|

Max. Facing head torque(NM)

|

4694

|

4694

|

|

Max. Spindle axial resistance (N)

|

31360

|

31360

|

|

Spindle taper

|

7:24 50#

|

7:24 50#

|

|

Worktabel travel

|

Long.

|

With rear column

|

1500

|

1500(Special)

|

|

Without rear column

|

2000(Special)

|

2000

|

|

Cross

|

1600

|

2000

|

|

Distance from spindle centerline to worktable surface

|

0-1400

|

0-1800

|

|

Max.spindle travel

|

900mm

|

900mm

|

|

Max.radial travel of facing head

|

250mm

|

250mm

|

|

Load capacity(kg)

|

Worktable at middle of slide

|

8000

|

10000

|

|

Worktable at ends of slide

|

6300

|

7000

|

|

Spindle speed range

|

8-800r/min

|

8-800r/min

|

|

Facing head speed range

|

2.5-125r/min

|

2.5-125r/min

|

|

Worktable area(LxW)

|

1600×1400(mm)

|

1800×1600(mm)

|

|

Worktable rapid rotary speed

|

1.2r/min

|

1.2r/min

|

|

Feed range of facing head slide

|

1-1560mm/min

|

1-1560mm/min

|

|

Reading accuracy of measure system

|

0.01mm

|

0.01mm

|

|

Boring accuracy and surface roughness

|

IT7,surface roughness within 3.2-1.6

|

IT7,surface roughness within 3.2-1.6

|

|

Machine size(LxWxH)

|

6995x3647x3442(mm)

|

7030x4665x3800(mm)

|

|

Machine weight(Kg)

|

24000

|

28000

|

TPX6113 TPX6113/2

PRODUCT FEATURES

The TPX series horizontal milling and boring machines are based ona classic design, suitable for rough and finished boring, capable ofmilling large and box type components. They excel at inner hold boringcylindrical turning and grooving by radial feed of facing plate. A 4x90optical positioning device allows for machining accuracy when turninglarge pieces. The precision digital read out measurement systemsensures accuracy of coordinates and lineation.

* Machine bed with larger specifications is added with integral auxiliary guideway

* Spindle system consists of three-layer structure, facing head spindle, hollow spindle and boring spindle

* The spindle with disk spring clamping and hydraulic unclamping makes tool handling easy

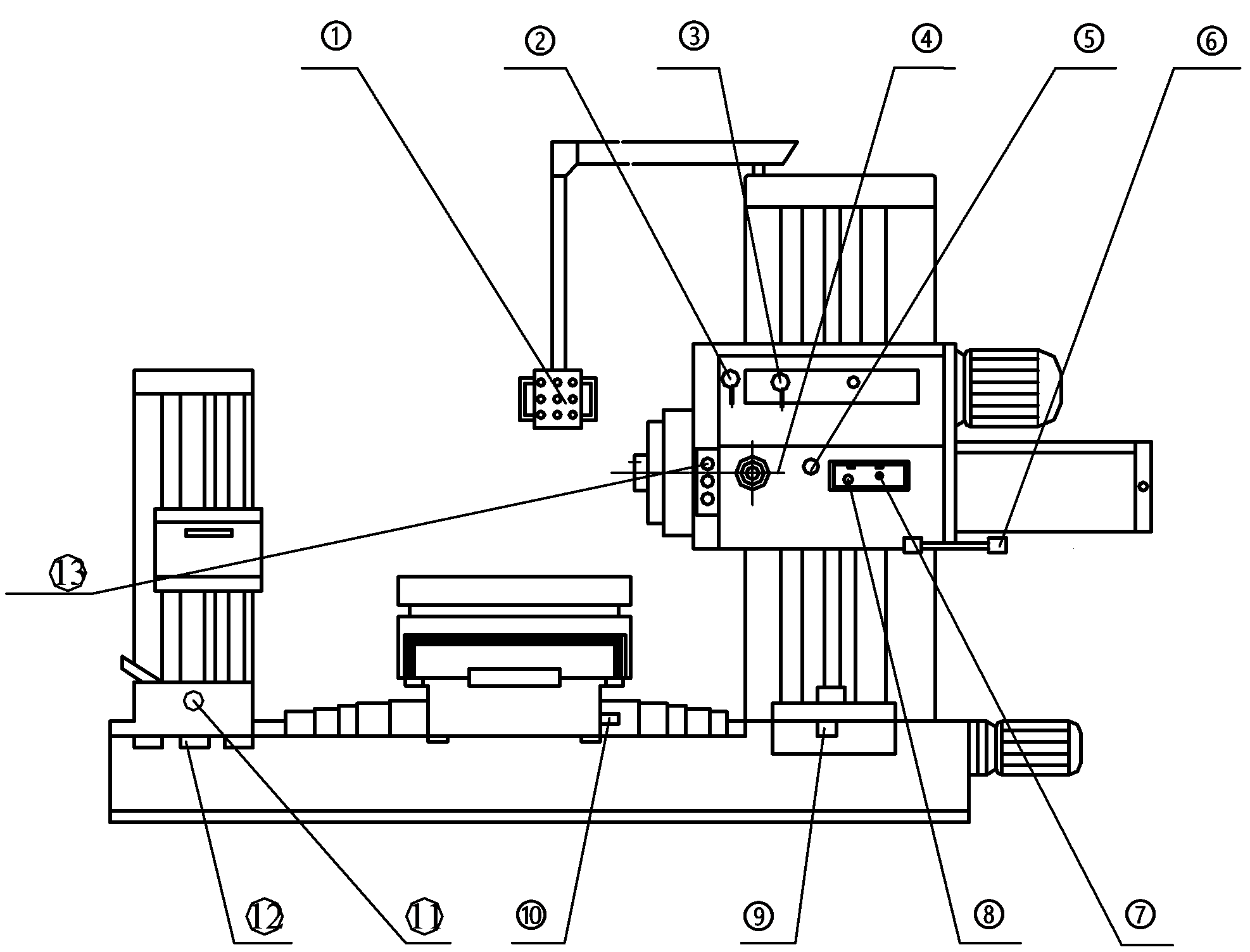

No. Name of the operation mechanism

1 Button station

2 Lever for engaging and disengaging of the facing head rotation

3 Lever for forward and reverse feed

4 Distributing lever of auto,micro and spindle feed(including radial slide)

<br /> 5 Distributing lever for the movement of spindle or radial slide on the facing head

6 Clamping lever of spindle

7 Rotating valve lever for the main movement speed change

8 Rotating lever for feed rate change

9 Lever hole for hand rough elevation of headstock

10 Lever hole for hand-driven rotation and longitudinal and cross movements of table

11 Lever hole for hand-driven longitudinal traverse and elevation of rear column

12 Clamping points of rear column (each points at back and front)

13 Distribution lever for longitudinal transverse of boring stay and elevation of boring stay slide

14 Emergency stop button(for 7:24 50#)

15 Tool unclamping button (for 7:24 50#)

16 Tool clamping button (for 7:24 50#)

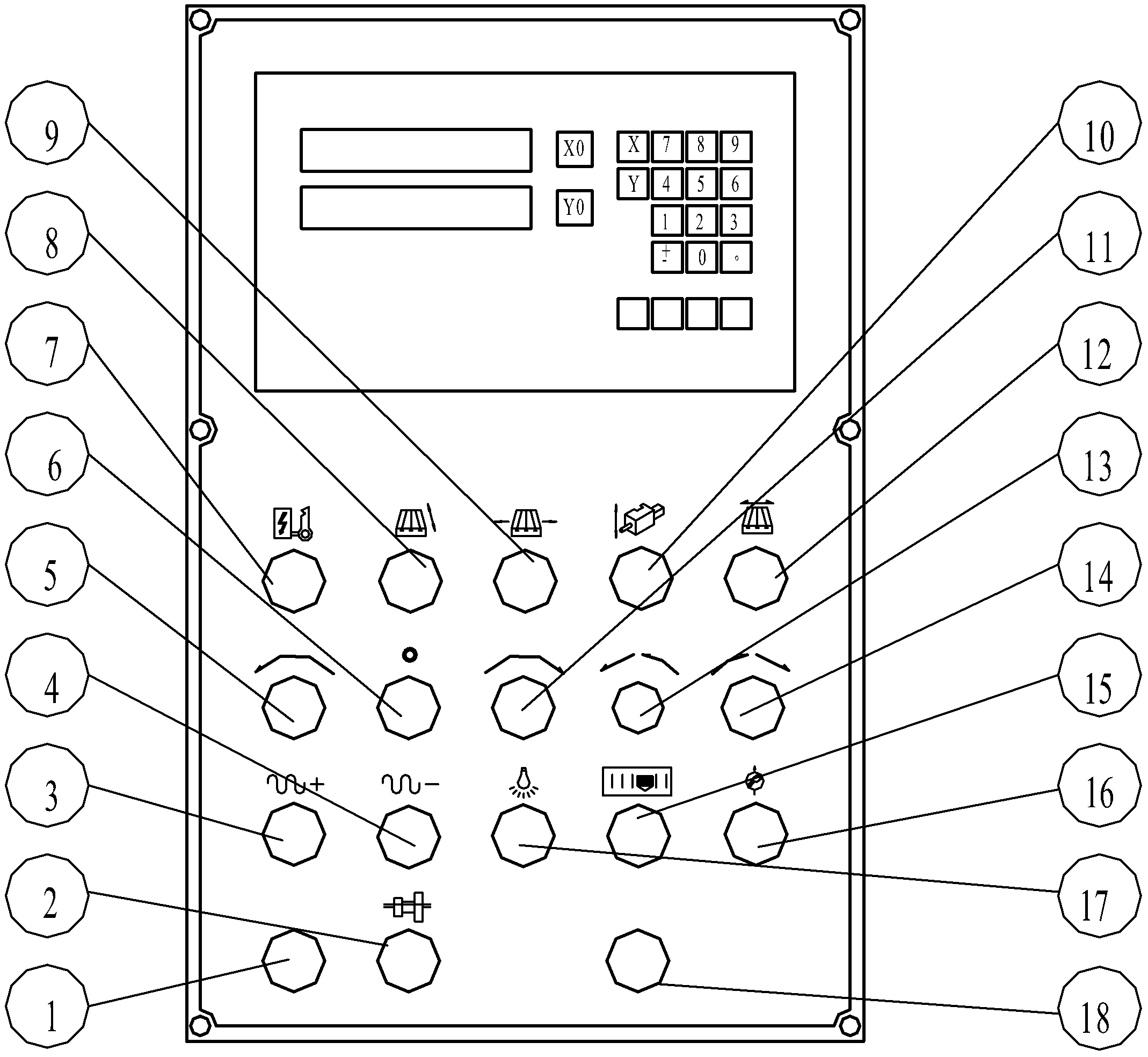

No. Description

1 Power supply indicator

2 Button for executing speed change

3 Forward rapid button

4 Reverse rapid button

5 Button for spindle or facing head rotating positively

6 Button for stopping main motor

7 Key switch

8 Button for transverse movement of table(with indicator)

9 Button for longitudinal movement of table(with indicator)

10 Button for lifting movement of headstock(with indicator)

11 Button for spindle or facing head rotating negtively

12 Button for rotation of table(with indicator)

13 Button for forward inching of spindle or facing head

14 Button for reverse inching of spindle or facing head

15 Button for optical illumination

16 Push-button for lubrication guideways

17 Switch for illuminating lamp

18 Emergency stop button