TPX6111B TPX6111B/2 TPX6111B/3

PRODUCT FEATURES

•The spindle speed range 8-1000r/min is realized by frequency conversion motor driving 2 gears.The spindle stepless speed is set and speed value is showed by setting buttons.

•Spindle taper is 7:24 No.50. This machine is equipped with automatic clamping/umclamping device which shorten auxilary time of clamping/umclamping tool and intensity of labor is reduced. The spindle features with good accuracy for a long time.

•Each coordinate axis moveing such as spindle, facing head slide, spindle box, longitudinal and cross movement of worktable and worktable rotation are all drove by AC servo motor mounted on bed. The feed stepless is set and the feed speed value is showed by setting buttons through gearbox, eletromagnitic clutch.

•The vertical axis is spindle box moving up and down, the traverse axis is worktable moving in cross direction and longitudinal axis is worktable moving in longitudinal direction which can be equipped with new type digital display meter with memory function. The machine features with full function and high accuracy.

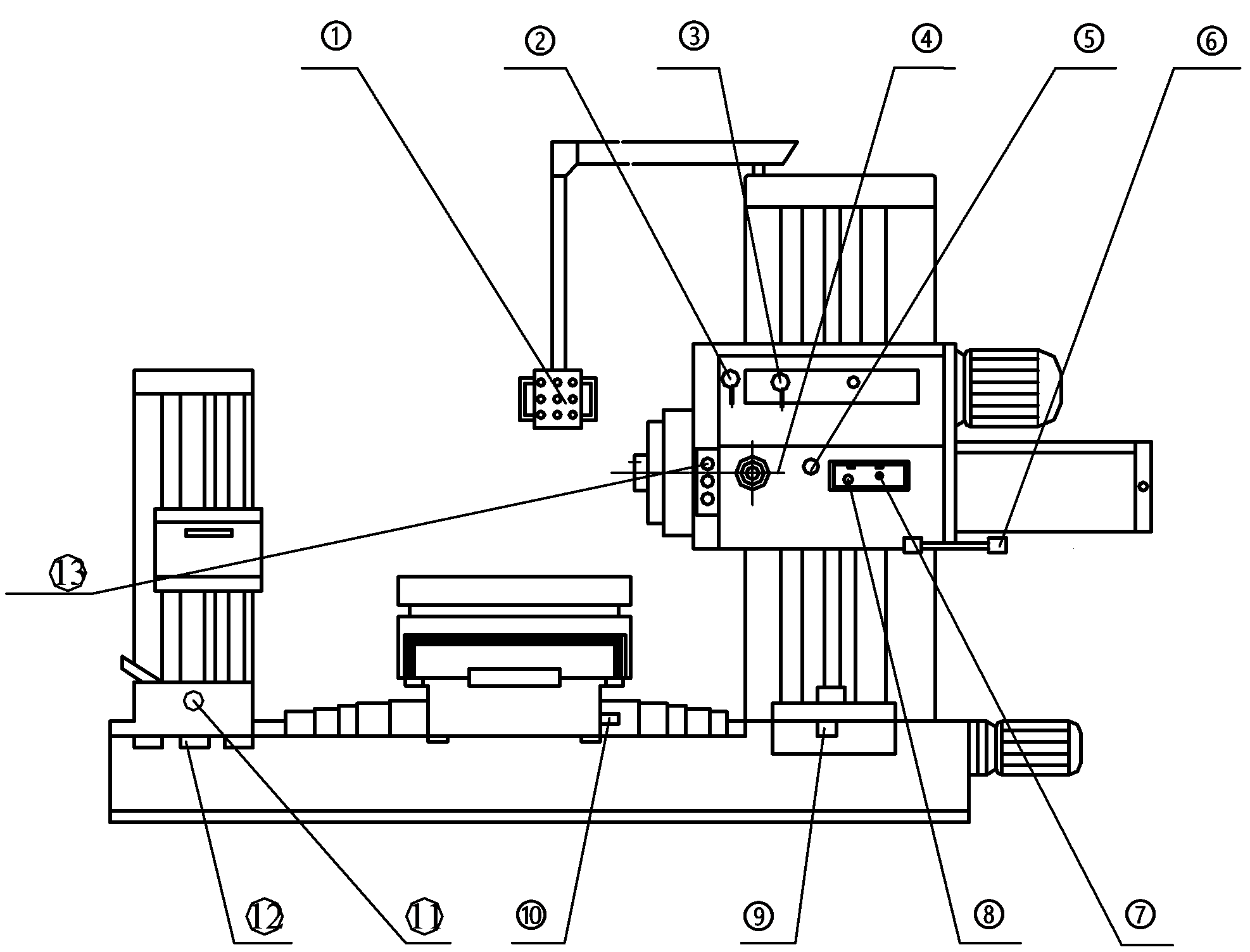

No. Name of the operation mechanism

1 Button station

2 Lever for engaging and disengaging of the facing head rotation

3 Lever for forward and reverse feed

4 Distributing lever of auto,micro and spindle feed(including radial slide)

<br /> 5 Distributing lever for the movement of spindle or radial slide on the facing head

6 Clamping lever of spindle

7 Rotating valve lever for the main movement speed change

8 Rotating lever for feed rate change

9 Lever hole for hand rough elevation of headstock

10 Lever hole for hand-driven rotation and longitudinal and cross movements of table

11 Lever hole for hand-driven longitudinal traverse and elevation of rear column

12 Clamping points of rear column (each points at back and front)

13 Distribution lever for longitudinal transverse of boring stay and elevation of boring stay slide

14 Emergency stop button(for 7:24 50#)

15 Tool unclamping button (for 7:24 50#)

16 Tool clamping button (for 7:24 50#)

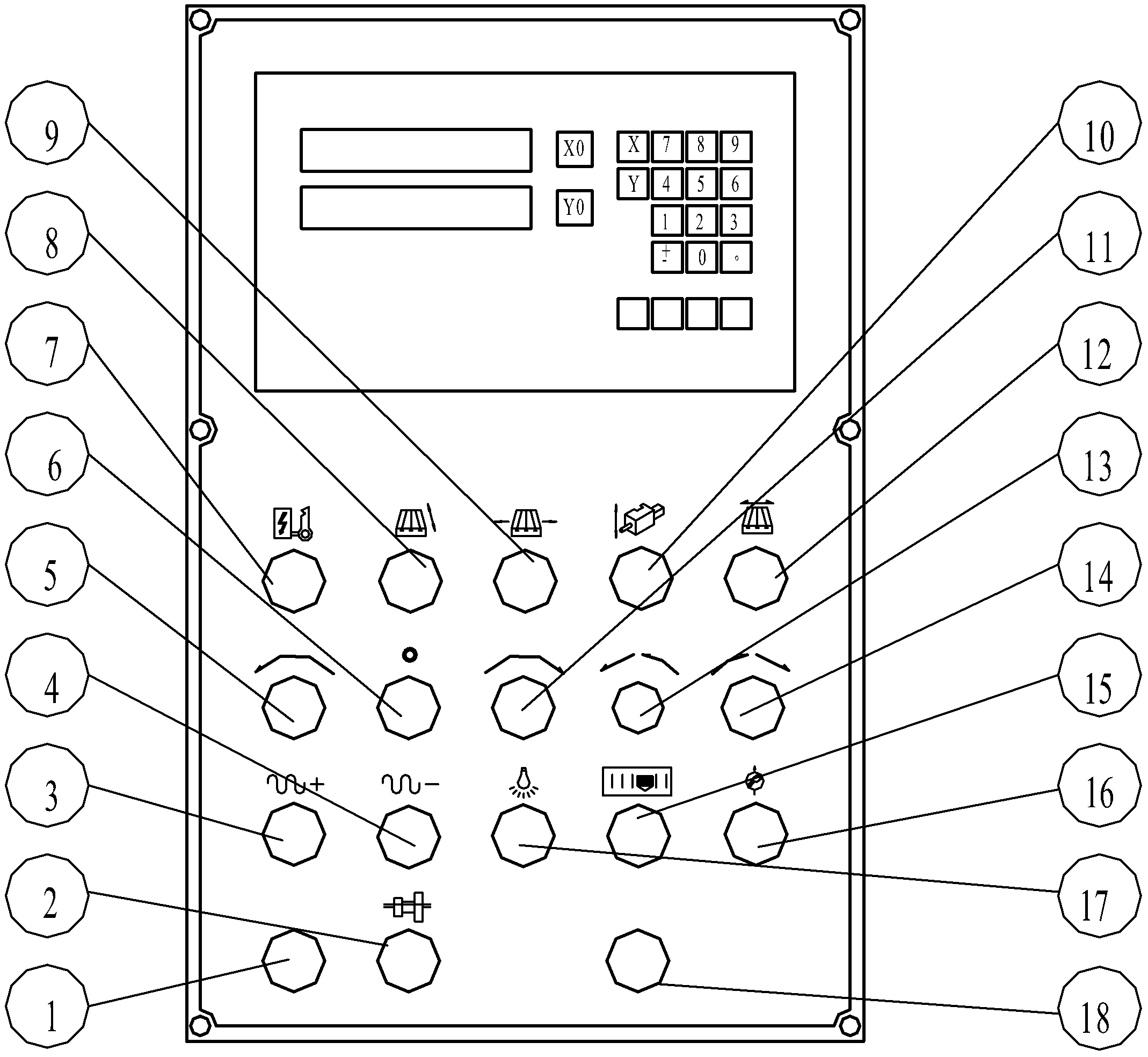

No. Description

1 Power supply indicator

2 Button for executing speed change

3 Forward rapid button

4 Reverse rapid button

5 Button for spindle or facing head rotating positively

6 Button for stopping main motor

7 Key switch

8 Button for transverse movement of table(with indicator)

9 Button for longitudinal movement of table(with indicator)

10 Button for lifting movement of headstock(with indicator)

11 Button for spindle or facing head rotating negtively

12 Button for rotation of table(with indicator)

13 Button for forward inching of spindle or facing head

14 Button for reverse inching of spindle or facing head

15 Button for optical illumination

16 Push-button for lubrication guideways

17 Switch for illuminating lamp

18 Emergency stop button

TPX6111B TPX6111B/2 TPX6111B/3

|

Item

|

|

Unit

|

TPX6111B

|

TPX6111B/2

|

TPX6111B/3

|

TPX6113

|

TPX6113/2

|

|

Spindle

|

Diameter

|

mm

|

110

|

110

|

110

|

130

|

130

|

|

Taper

|

–

|

Morse No6

(ISO7:24No50)

|

Morse No6

(ISO7:24No50)

|

Morse No6

(ISO7:24No50)

|

Metric 80

(ISO7:24No50)

|

Metric 80

(ISO7:24No50)

|

|

Max Torque

|

N.m

|

1225

|

1225

|

1225

|

3136

|

3136

|

|

Max Axial Thrust

|

N

|

12250

|

12250

|

12250

|

31360

|

31360

|

|

Speed Settings

|

–

|

22

|

22

|

22

|

24

|

24

|

|

Speed Range

|

r/min

|

8-1000

|

8-1000

|

8-1000

|

4-800

|

4-800

|

|

Main Motor Power

|

kW

|

7.5

|

7.5

|

7.5

|

15

|

15

|

|

Facing Plate

|

Max Torque

|

N.m

|

1960

|

1960

|

1960

|

4900

|

4900

|

|

Diameter

|

mm

|

600

|

600

|

600

|

750

|

750

|

|

Speed Range

|

r/min

|

4-200

|

4-200

|

4-200

|

2.5-125

|

2.5-125

|

|

Speed Settings

|

–

|

18

|

18

|

18

|

18

|

18

|

|

Worktable

|

Dimensions

|

mm

|

1100×960

|

1100×960

|

1250×1100

|

1600×1400

|

1800×1600

|

|

Max Load

|

kg

|

5000

|

5000

|

5000

|

8000

|

10000

|

|

T-slot Size

|

mm

|

22

|

22

|

22

|

28

|

28

|

|

T-slot Count

|

一

|

7

|

7

|

7

|

9

|

11

|

|

Machining Range

|

X-axis Max Travel

|

mm

|

900

|

1250

|

1600

|

1600

|

2000

|

|

Y-axis Max Travel

|

mm

|

900

|

900

|

1200

|

1400

|

1800

|

|

Z-axis Max Travel

|

mm

|

1400

|

1400

|

1400

|

2000

|

2000

|

|

W-axis Max Travel(Spindle)

|

mm

|

600

|

600

|

600

|

900

|

900

|

|

U-axis Max Travel(Facing Plate Slide)

|

mm

|

180

|

180

|

180

|

250

|

250

|

|

B-axis Rotary Angle

|

。

|

360

|

360

|

360

|

360

|

360

|

|

Min Distance Between Spindle Centerline and Worktable

|

mm

|

0

|

0

|

0

|

0

|

0

|

|

Feed

|

Rapid Traverse

|

mm/min

|

X/Y/Z/W:2500

|

X/Y/Z/W:2500

|

X/Y/Z/W:2500

|

X/Y/Z/W:2500

|

X/Y/Z/W:2500

|

|

Feed range of axes for each spindle revolution

|

mm/rev

|

0.04-6/0.01-1.88

(X/Y/Z/W)

|

0.04-6/0.01-1.88

(X/Y/Z/W)

|

0.04-6/0.01-1.88

(X/Y/Z/W)

|

0.05-8/0.01-2

(X/Y/Z/W)

|

0.05-8/0.01-2

(X/Y/Z/W)

|

|

Speed Range (X)

|

mm/min

|

–

|

–

|

–

|

–

|

–

|

|

Accuracy

|

Linear Measurement Reading Accuracy (X/Y/Z-axis)

|

mm

|

0.005

|

0.005

|

0.005

|

0.005

|

0.005

|

|

Linear Measurement Reading Accuracy (B-axis)

|

。

|

0.001

|

0.001

|

0.001

|

0.001

|

0.001

|

|

General Specs

|

Dimensions(LxWxH)

|

mm

|

4910x2454x2750

|

4910x2870x2750

|

5028x3359x3079

|

6995x3647x3442

|

7030x4665x3800

|

|

Machine Weight

|

kg

|

11500

|

13000

|

14000

|

24000

|

28000

|

TPX6111B TPX6111B/2 TPX6111B/3

PRODUCT FEATURES

•The spindle speed range 8-1000r/min is realized by frequency conversion motor driving 2 gears.The spindle stepless speed is set and speed value is showed by setting buttons.

•Spindle taper is 7:24 No.50. This machine is equipped with automatic clamping/umclamping device which shorten auxilary time of clamping/umclamping tool and intensity of labor is reduced. The spindle features with good accuracy for a long time.

•Each coordinate axis moveing such as spindle, facing head slide, spindle box, longitudinal and cross movement of worktable and worktable rotation are all drove by AC servo motor mounted on bed. The feed stepless is set and the feed speed value is showed by setting buttons through gearbox, eletromagnitic clutch.

•The vertical axis is spindle box moving up and down, the traverse axis is worktable moving in cross direction and longitudinal axis is worktable moving in longitudinal direction which can be equipped with new type digital display meter with memory function. The machine features with full function and high accuracy.

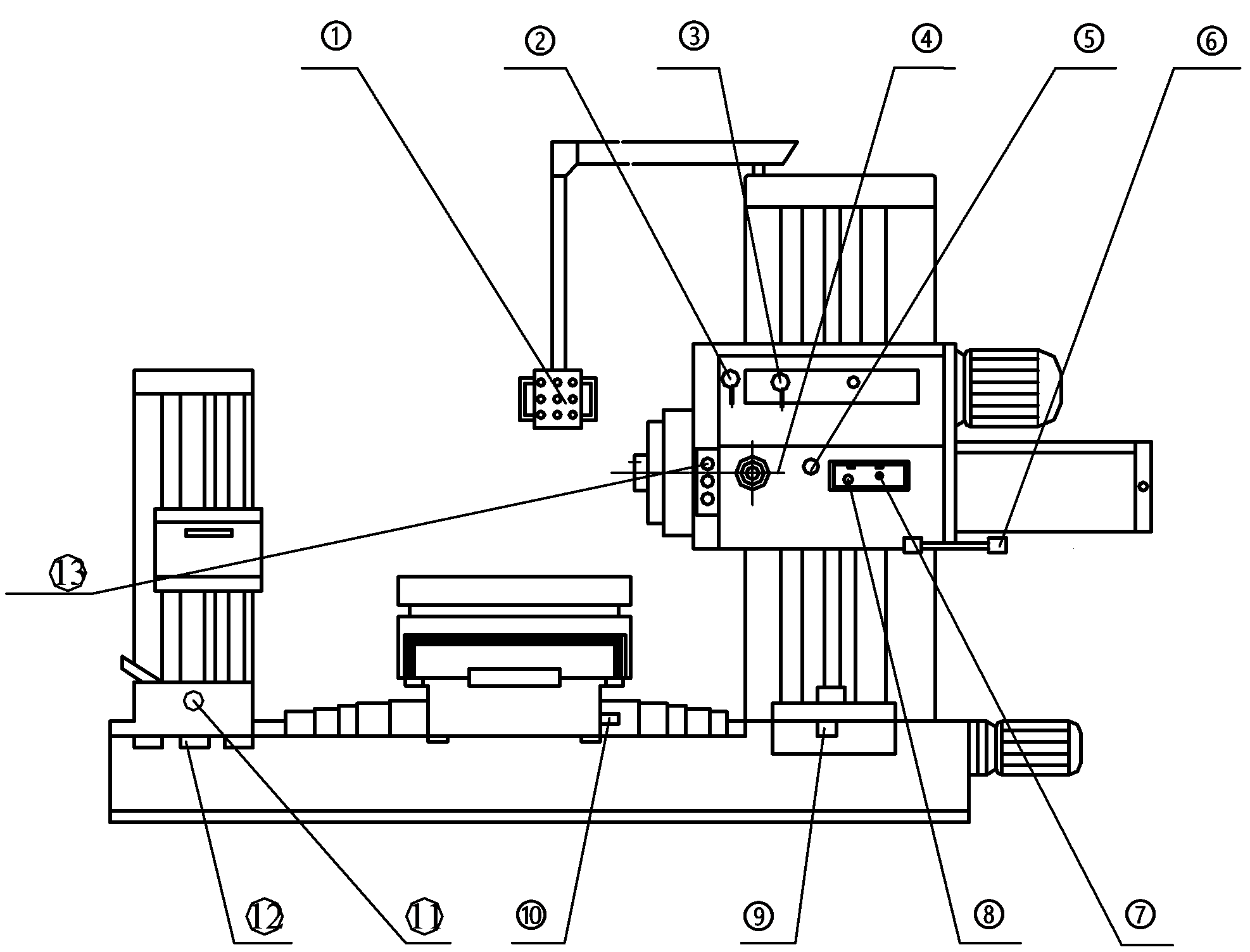

No. Name of the operation mechanism

1 Button station

2 Lever for engaging and disengaging of the facing head rotation

3 Lever for forward and reverse feed

4 Distributing lever of auto,micro and spindle feed(including radial slide)

<br /> 5 Distributing lever for the movement of spindle or radial slide on the facing head

6 Clamping lever of spindle

7 Rotating valve lever for the main movement speed change

8 Rotating lever for feed rate change

9 Lever hole for hand rough elevation of headstock

10 Lever hole for hand-driven rotation and longitudinal and cross movements of table

11 Lever hole for hand-driven longitudinal traverse and elevation of rear column

12 Clamping points of rear column (each points at back and front)

13 Distribution lever for longitudinal transverse of boring stay and elevation of boring stay slide

14 Emergency stop button(for 7:24 50#)

15 Tool unclamping button (for 7:24 50#)

16 Tool clamping button (for 7:24 50#)

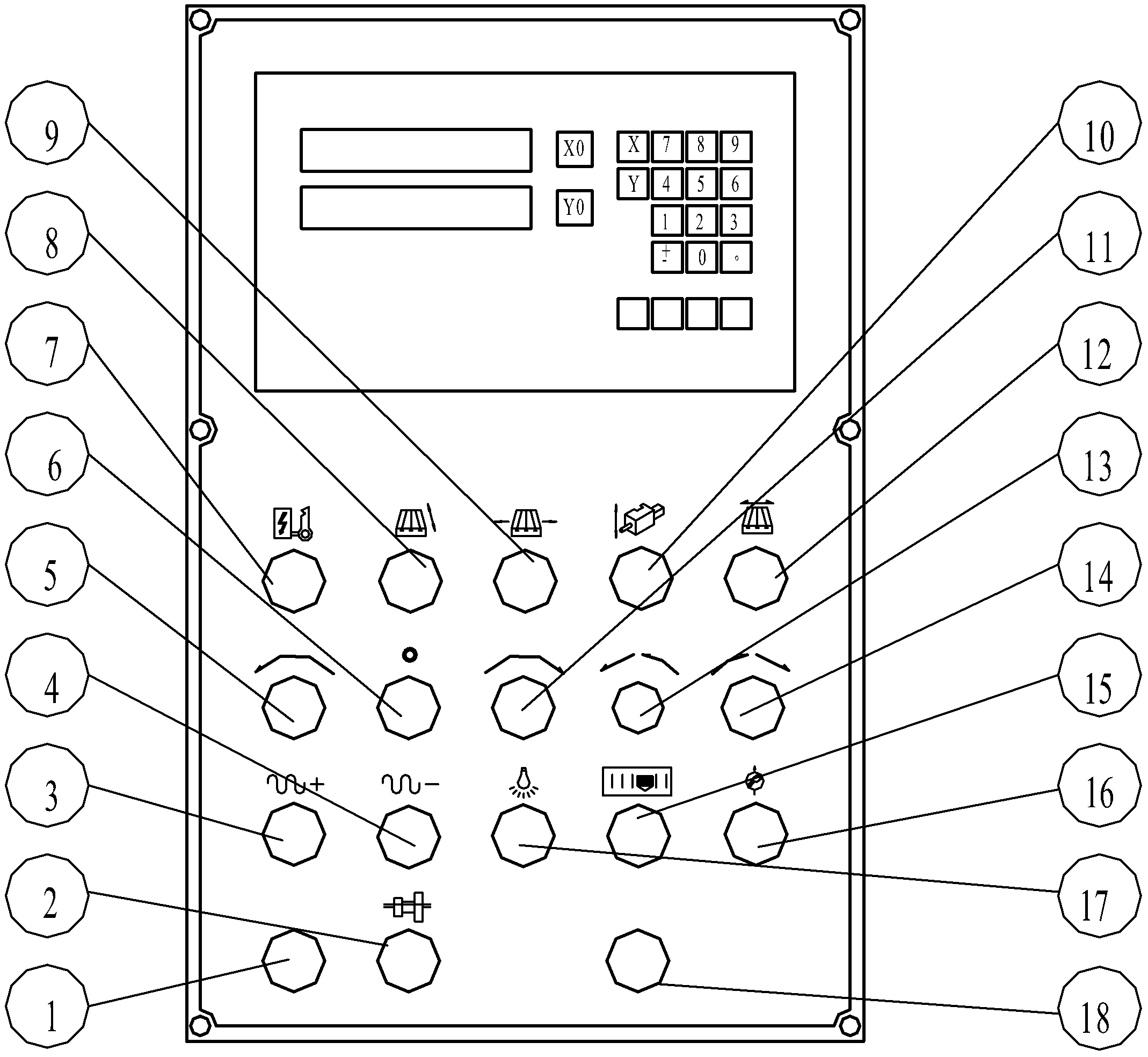

No. Description

1 Power supply indicator

2 Button for executing speed change

3 Forward rapid button

4 Reverse rapid button

5 Button for spindle or facing head rotating positively

6 Button for stopping main motor

7 Key switch

8 Button for transverse movement of table(with indicator)

9 Button for longitudinal movement of table(with indicator)

10 Button for lifting movement of headstock(with indicator)

11 Button for spindle or facing head rotating negtively

12 Button for rotation of table(with indicator)

13 Button for forward inching of spindle or facing head

14 Button for reverse inching of spindle or facing head

15 Button for optical illumination

16 Push-button for lubrication guideways

17 Switch for illuminating lamp

18 Emergency stop button