W24S-75 Rolling Pipe Hydraulic Section Bender machine

Section Bending Machine Pipe Profile Bending Machine Vertical Section Aluminum Profile Bending Machine

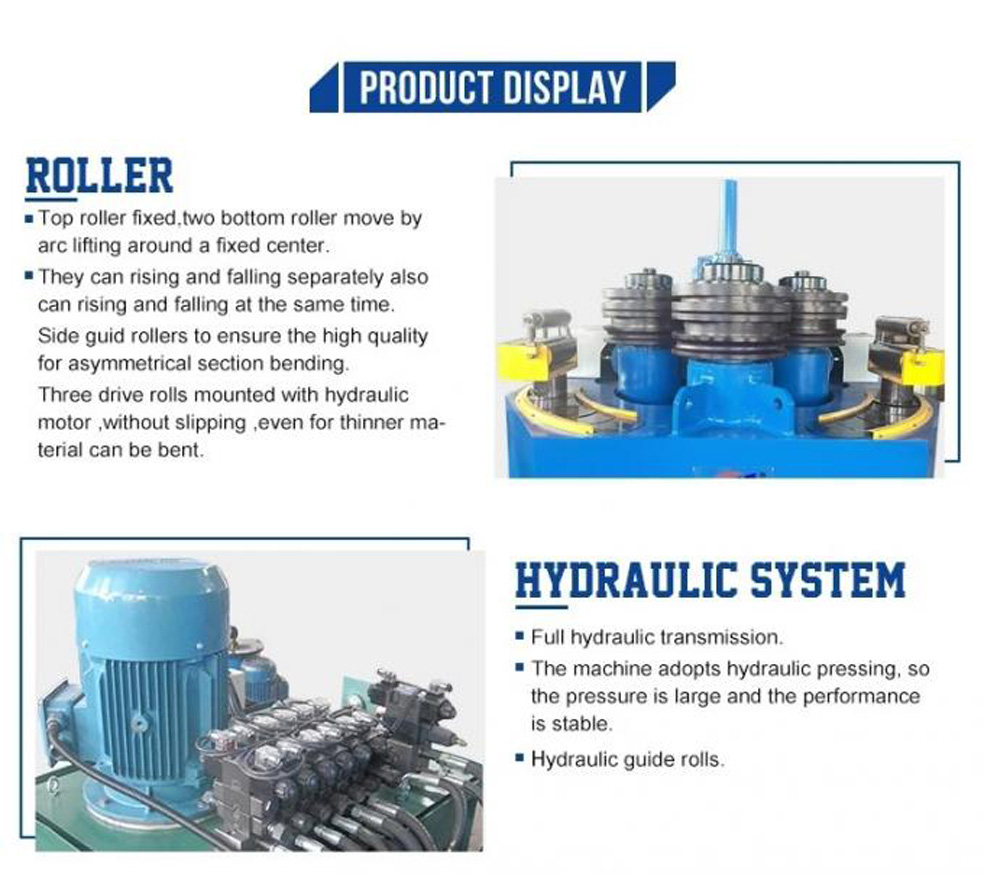

Hydraulic 3 roller profile/ section bending machine, which mainly use in various steel profile bending.

It can roll " O " spiral and etc. shape work pieces. It is widely in petrol, chemical, shipyard, metal working

and machine manufacturing industries.Three rollers are main droved,can do the prebending,through

adjusting the guide rollers.it is easy to correct the deformation from the bending process.

(1) Uses the microcomputer control, automatic bending;

(2) Safety: the emergency stop button on the bending arm;

(3) Dialogue operation, easy to study and understand;

(4) High pipe-bending precision up to ±0.15°;

(5) 1000 groups pipe-bending information storage, all angles work forms a coherent whole;

(6) The mandrel automatically in and out, saving much time;

(7) Suitable for bending steel pipe, stainless steel pipe, copper pipe, aluminum pipe, etc;

(8) Can install auxiliary push die, low returning-core function, can bend thin pipes;

(9) Special fitting: special mold, anti-wrinkle board, auxiliary push installation, etc.

(1) Factory guarantees machinery well packed and testing qualified before shipment.

(2) Factory guarantees all the goods are brand-new; no defects for the specifications or materials used.

(3) 1-year quality warranty after customer accepts the inspection for machinery’s trial operation.

W24S-75 Rolling Pipe Hydraulic Section Bender machine

Technical

parameter

|

Model&spec.

|

W24S-6

|

W24S-16

|

W24S-30

|

W24S-45

|

W24S-75

|

W24S-100

|

W24S-140

|

|

Max

bending modulus of section (cm3)

|

6

|

16

|

30

|

45

|

75

|

100

|

140

|

|

Bending

speed(m/min)

|

5.5

|

5.5

|

5.5

|

5.5

|

5

|

5

|

5

|

|

yield

limit of material (MPa)

|

245

|

245

|

245

|

245

|

245

|

245

|

245

|

|

inward

bending of angle steel

|

The

max cross section (mm)

|

50×5

|

80×8

|

90×10

|

100×10

|

120×12

|

140×16

|

150×16

|

|

The min

bending diameter (mm)

|

800

|

1000

|

1200

|

1500

|

2000

|

2500

|

2400

|

|

The min

cross section (mm)

|

20×3

|

30×3

|

35×3

|

36×5

|

38×4

|

40×5

|

50×5

|

|

The min

bending diameter (mm)

|

400

|

550

|

560

|

600

|

600

|

720

|

1000

|

|

outward

bending of angle steel

|

The

max cross section (mm)

|

50×5

|

80×8

|

90×10

|

100×10

|

120×12

|

140×16

|

150×16

|

|

The min

bending diameter (mm)

|

800

|

1000

|

1100

|

1300

|

1600

|

1800

|

2200

|

|

The min

cross section (mm)

|

20×3

|

30×3

|

35×3

|

36×5

|

38×4

|

45×5

|

50×5

|

|

The min

bending diameter (mm)

|

400

|

550

|

500

|

600

|

700

|

760

|

400

|

|

outward

bending of channel steel

|

channel

steel model

|

8

|

12

|

16

|

20

|

25

|

28

|

30

|

|

The min

bending diameter (mm)

|

600

|

800

|

800

|

1000

|

1100

|

1100

|

1200

|

|

inward

bending of channel steel

|

channel

steel model

|

8

|

12

|

16

|

20

|

25

|

28

|

30

|

|

The min

bending radius (mm)

|

700

|

900

|

1000

|

1150

|

1600

|

1700

|

1700

|

|

plane

bending of flat steel

|

The

max cross section (mm)

|

100×18

|

150×25

|

180×25

|

200×30

|

220×40

|

250×40

|

280×50

|

|

The min

bending diameter (mm)

|

600

|

700

|

800

|

900

|

1000

|

1200

|

1300

|

|

vertical

bending of flat steel

|

The

max cross section (mm)

|

50×12

|

75×16

|

90×20

|

100×25

|

110×40

|

120×40

|

150×40

|

|

The min

bending diameter (mm)

|

500

|

760

|

800

|

1000

|

1100

|

1300

|

1500

|

|

bending of

round pipe

|

The

max cross section (mm)

|

42×4

|

76×4.5

|

89×5

|

89×8

|

114×5

|

159×5

|

168×6

|

|

The min

bending diameter (mm)

|

500

|

750

|

900

|

900

|

1200

|

2000

|

2000

|

|

bending of

round bar

|

The

max cross section (mm)

|

38

|

52

|

62

|

75

|

85

|

90

|

100

|

|

The min

bending diameter (mm)

|

450

|

600

|

600

|

800

|

100

|

1100

|

1200

|

|

bending of

square pipe

|

The

max cross section (mm)

|

45×3

|

60×4

|

70×4

|

80×6

|

90×8

|

100×10

|

125×10

|

|

The min

bending diameter (mm)

|

750

|

900

|

1000

|

1200

|

1600

|

2000

|

2500

|

W24S-75 Rolling Pipe Hydraulic Section Bender machine

Section Bending Machine Pipe Profile Bending Machine Vertical Section Aluminum Profile Bending Machine

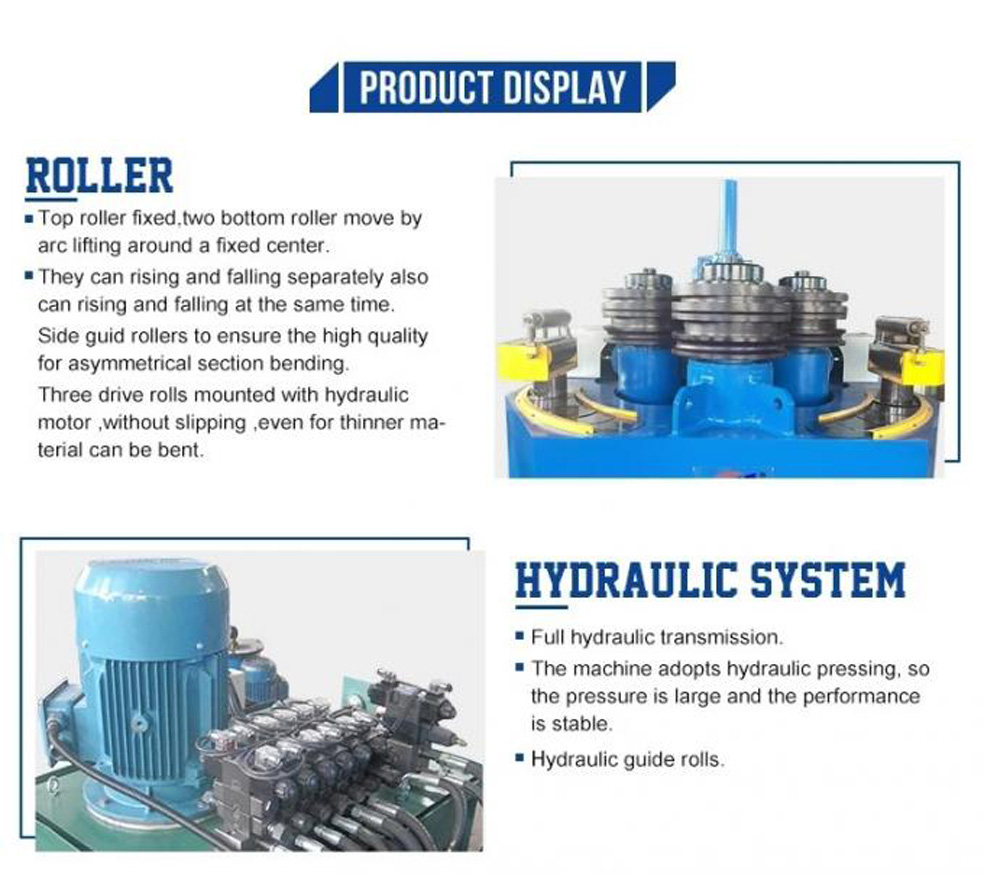

Hydraulic 3 roller profile/ section bending machine, which mainly use in various steel profile bending.

It can roll " O " spiral and etc. shape work pieces. It is widely in petrol, chemical, shipyard, metal working

and machine manufacturing industries.Three rollers are main droved,can do the prebending,through

adjusting the guide rollers.it is easy to correct the deformation from the bending process.

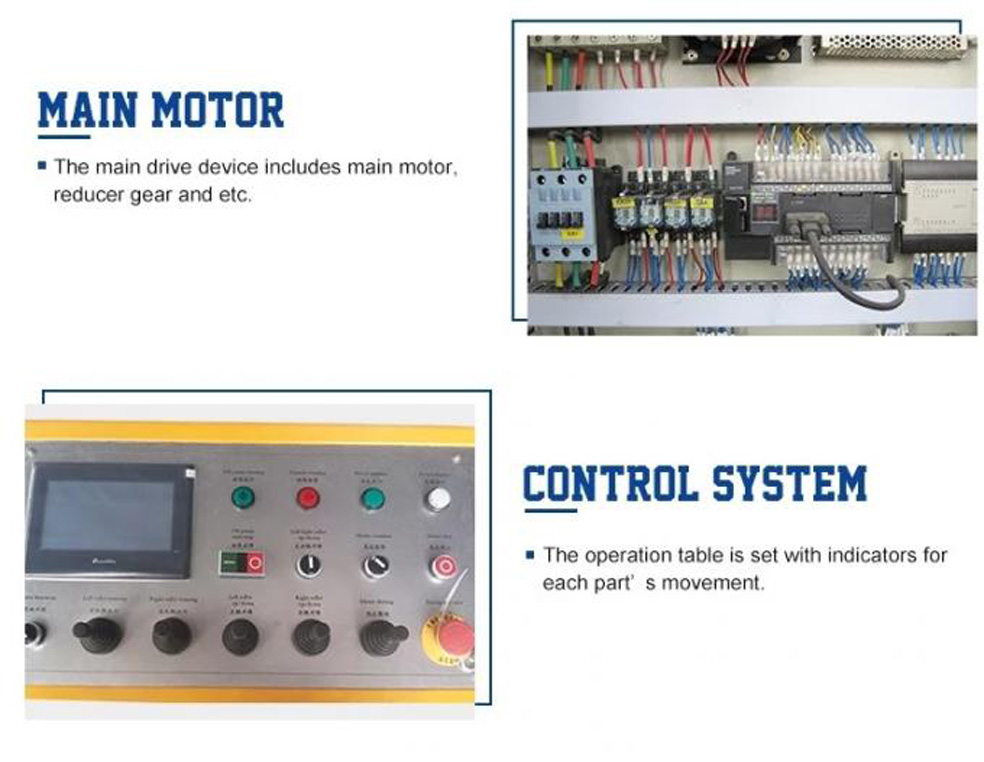

(1) Uses the microcomputer control, automatic bending;

(2) Safety: the emergency stop button on the bending arm;

(3) Dialogue operation, easy to study and understand;

(4) High pipe-bending precision up to ±0.15°;

(5) 1000 groups pipe-bending information storage, all angles work forms a coherent whole;

(6) The mandrel automatically in and out, saving much time;

(7) Suitable for bending steel pipe, stainless steel pipe, copper pipe, aluminum pipe, etc;

(8) Can install auxiliary push die, low returning-core function, can bend thin pipes;

(9) Special fitting: special mold, anti-wrinkle board, auxiliary push installation, etc.

(1) Factory guarantees machinery well packed and testing qualified before shipment.

(2) Factory guarantees all the goods are brand-new; no defects for the specifications or materials used.

(3) 1-year quality warranty after customer accepts the inspection for machinery’s trial operation.