Five axis horizontal boring & milling machining center HBM-110T2/110T3/130T2/130T3/160T4

High-torque

The maximum torque output of the main shaft is 2838nm , which is the largest of similar products

The nose type spindle head can approach the workpiece when machining, and is suitable forheavy cutting.

The rotating workbench is equipped with a standard bearing capacity of 8000kg and aroptional bearing capacity of 10000~25000kg.

The z-axis can continuously bear the axial load of 2000kgf, ensuring high torque and higlspeed to provide extremely high cutting force.

High-rigidity

The main shaft bearing is cooled by circulating oil, and the surrounding is equipped withtubingjacket cooling design to avoid thermal displacement.

The flange part of the main shaft motor is cooled by oil pipe sheath.

After special nitriding treatment, the main shaft can be used for a long time without wearing

X/y/z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

High-precision

The casting structure is composed of high-grade cast iron with good stability andstrong seismic resistance and arch bridge type high rigid structure

The bending and torsional rigidity of the column is increased by 1.7 times, and thestable processing can be carried out on the top side of the y-axis stroke enc

The combination ofthe spindle treated by nitriding and ultra deep cooling (- 190 °c) and thspindle bearing with high precision and rigidity can give full play to the best performance othe product for a long tim

Standard accessories

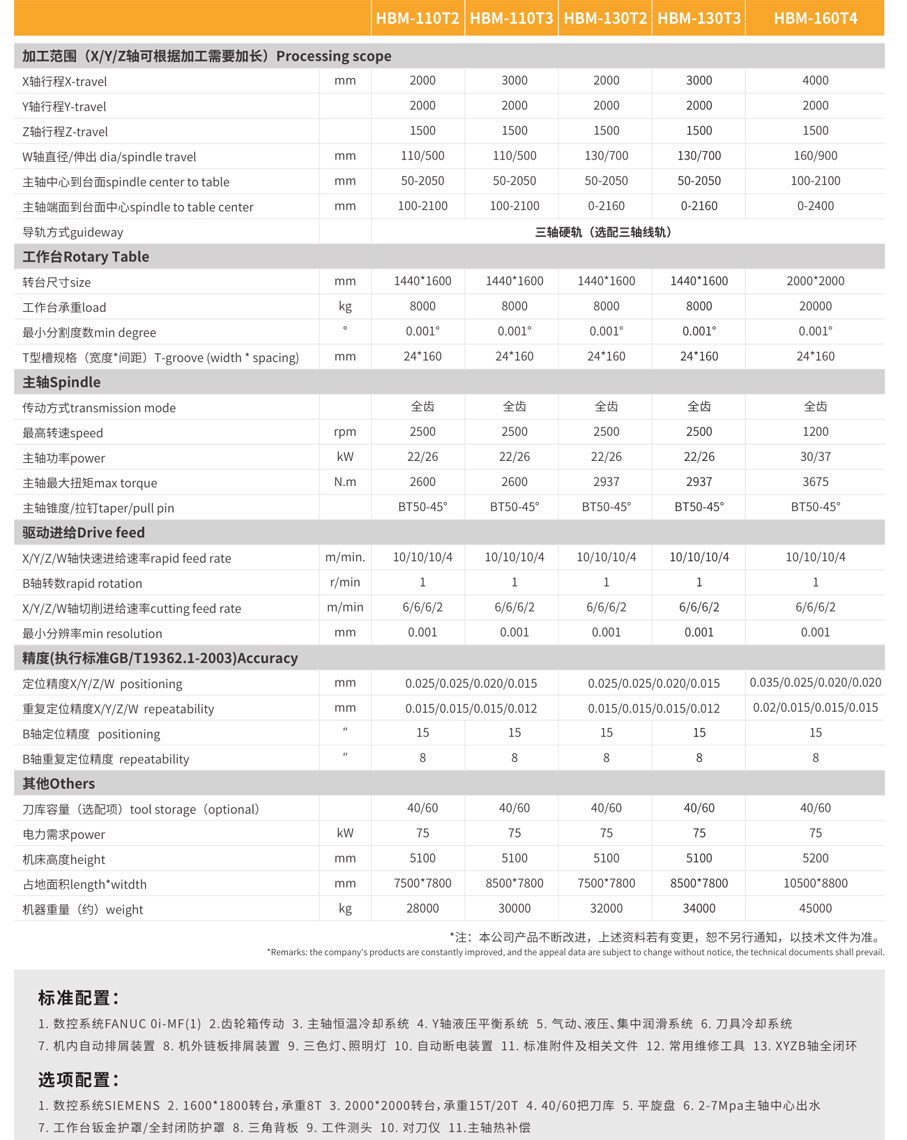

1. CNC system FANUC Oi-MF (1)

2. Gearbox transmission

3. Spindle constant temperature cooling system

4. Y-axis hydraulic balance system

5. Pneumatic, hydraulic, centralized lubrication system

6. Tool cooling system

7. Automatic chip removal device inside the machine

8. Chain plate chip removal device outside the machine

9. Three-color light, lighting lamp

10. Automatic power off device

11. XYZB axis full closed loop

Optional accessories:

1. CNC system SIEMENS

2. 1600*1800 turntable, load-bearing 8T

3. 2000*2000 turntable, load-bearing 15T/20T

4. 40/60 tool magazine

5. Flat rotary table

6. 2-7Mpa spindle center water outlet,

7. Worktable sheet metal cover/fully enclosed protective cover

8. Triangular back plate

9. Workpiece probe

10. Tool setting instrument

11. Spindle thermal compensation

Five axis horizontal boring & milling machining center HBM-110T2/110T3/130T2/130T3/160T4

High-torque

The maximum torque output of the main shaft is 2838nm , which is the largest of similar products

The nose type spindle head can approach the workpiece when machining, and is suitable forheavy cutting.

The rotating workbench is equipped with a standard bearing capacity of 8000kg and aroptional bearing capacity of 10000~25000kg.

The z-axis can continuously bear the axial load of 2000kgf, ensuring high torque and higlspeed to provide extremely high cutting force.

High-rigidity

The main shaft bearing is cooled by circulating oil, and the surrounding is equipped withtubingjacket cooling design to avoid thermal displacement.

The flange part of the main shaft motor is cooled by oil pipe sheath.

After special nitriding treatment, the main shaft can be used for a long time without wearing

X/y/z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

High-precision

The casting structure is composed of high-grade cast iron with good stability andstrong seismic resistance and arch bridge type high rigid structure

The bending and torsional rigidity of the column is increased by 1.7 times, and thestable processing can be carried out on the top side of the y-axis stroke enc

The combination ofthe spindle treated by nitriding and ultra deep cooling (- 190 °c) and thspindle bearing with high precision and rigidity can give full play to the best performance othe product for a long tim